Thailand's prefabricated steel painting factory project.

Thailand's prefabricated steel painting factory project.

Starting construction in 2016 and finished half a year later, this was one of Universal Steel Buildings first projects. Constructed for a water paint manufacturer, the investors and general managers had strict guidelines when it comes to the construction of the factory for painting, more specifically the requirement for the cost-effectiveness of the structure.

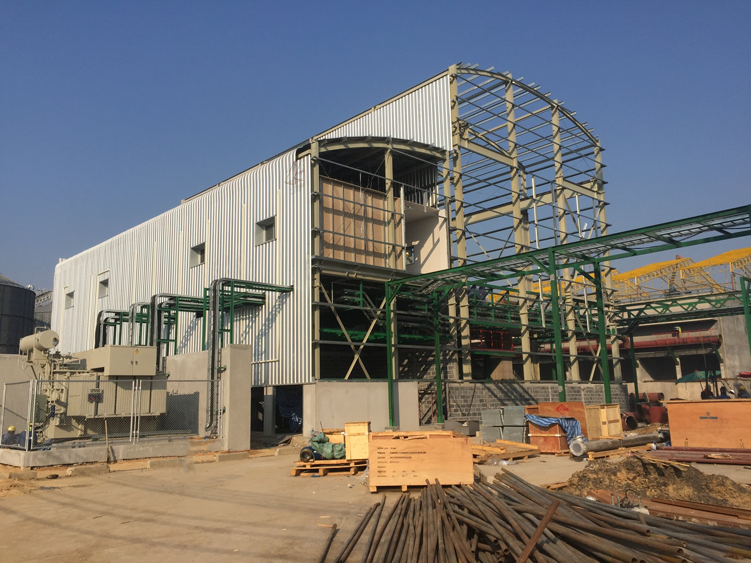

Steel painting factory exerior.

Project Summary.

Every decision was made with efficiency in mind. For example, the area with high foot traffic occurs when workers move from their locker rooms/lavatory to the painting factory area, this meant the distance between the two should not be too far away.

With the nature of the factory, silos, and silos brackets must be installed to store raw material/paint within the structure itself, and accompanying the silos are scaffolding structures that are used to traverse the tall silos.

Other than that, there are more requirements that are specific to a painting factory that we provided such as a mezzanine for machinery and a temporary warehouse extension for products that are ready for transportation.

Painting material silos.

Erection in the progress of painting factory.

Painting Factory Building Process.

The entire process for this painting factory is done through a 6 steps process.

First, consultation, The project went through multiple rounds of revision to make sure the vision of the owners and the economic efficiency suitable for a painting manufacturing factory is met, either by taking out unnecessary parts or adding more features that the project would require. We always wish to perform above and beyond what was promised in order to increase customer satisfaction.

The second is designing, all customers up to this point will receive free designs and revisions until a satisfactory result is reached. This step would be at the same time as the consultation and going through multiple revisions for the painting factory, after the final decision is made, the design is finalized and sent out to the factory to begin manufacturing. The design itself is simple, engineers and designers slice the model into multiple squares and parts that can be used for ease of manufacturing and construction.

Fabrication is the third step, the design is now sent to the factory for manufacturing and each part goes through a rigorous process of quality control. Each part must be measured and must have no more than a 5mm difference in thickness. Each part can also be painted with anti-corrosion, fire deterrents, or galvanizing coat if the painting factory client requires so.

Shipping, After the finished product for the painting factory, is done, it's strapped onto a container, the parts now must travel to the construction site using the mode of transportation most suitable for the client. In this phase, we cover a wide variety of payment methods to suit each individual client's needs and wants.

Finally, is erection and maintenance, using the blueprint, the site engineer will move part by part assembling, this compared to traditional construction with concrete take significantly less time to complete, saving precious time, this could vary; however, due to the complex of a project, but the painting factory was a such a simple process that no time at all was wasted. With the project finished, our clients automatically get registered into our maintenance system for support in the future, with the main structure receiving up to 20 years of warranty.

-----------------------------------------------------------

At Universal Vietnam Steel Buildings, we aim to give you the best product and services through value engineering, beneficial costs, and payment plans with a highly trained and committed team.

Check out our information on Dun & Bradstreet or Yellow Pages.

To find out more about how you can start your project today, contact us through our Online Form System or call/text +84 981 973 499 on WhatsApp.