Construction techniques in warehouse maintenance: A key to quality

Construction techniques in warehouse maintenance directly impact the long-term quality and durability of a facility. To build a sustainable warehouse, it is essential to follow technical standards and carry out periodic maintenance.

1. The critical role of construction techniques in warehouse maintenance

In the industrial construction sector, warehouse maintenance is not merely about fixing what's broken — it's a long-term strategy to protect assets.

Understanding how construction techniques play a vital role in determining post-maintenance quality is crucial. Let's explore the key reasons:

- Preserve structural integrity and extend lifespan: Accurate construction techniques address weak points like roof joints, gutters, and steel frames, enhancing durability and load resistance.

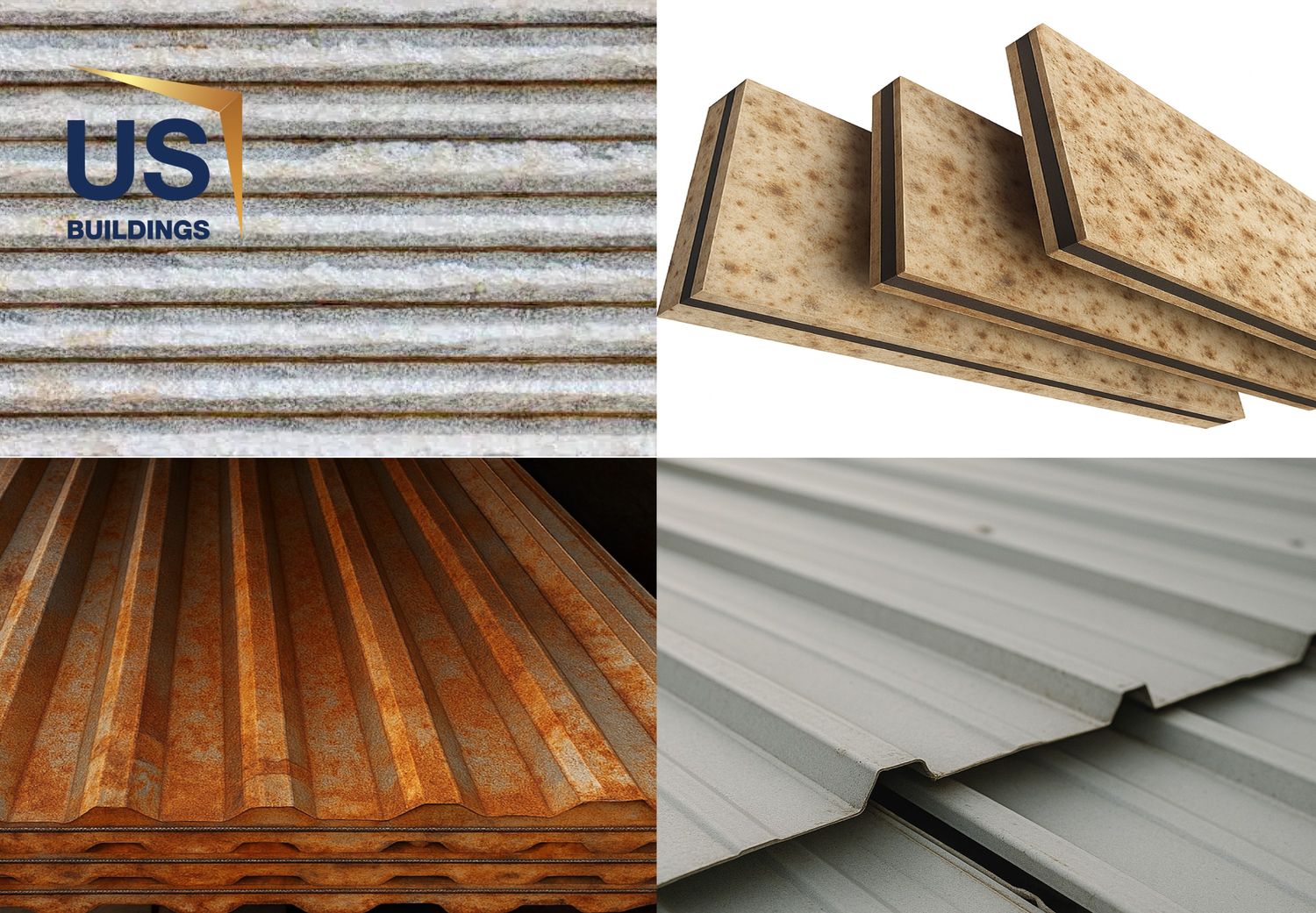

Image 1. Strict requirements for construction techniques

- Optimize repair costs and long-term operations: Proper technical execution reduces repeated repairs, helping businesses cut unnecessary operational expenses.

- Ensure safety for people and property: Quality construction prioritizes absolute safety for workers, electrical systems, and warehouse assets by complying with safety standards and using certified equipment.

2. Common construction mistakes and their consequences in warehouse repair

Many businesses choose warehouse repair services based on low cost rather than evaluating actual construction techniques, resulting in serious technical errors. Common mistakes include:

Image 2. Regular warehouse leak prevention ensures occupational safety during operations

- Incorrect metal roof leak fixing: Poor patching or ignoring rust beneath causes recurrent leakage within months.

- Substandard materials used: Low-grade sealants and coatings drastically reduce the building's service life.

- Neglecting drainage system inspection: Blocked gutters cause wall seepage, foundation damage, and reduce the effectiveness of warehouse leak prevention, especially during long rainy seasons.

- Lack of proper technical supervision: Site supervisors are critical to ensuring compliance with construction standards and safety regulations throughout the project.

3. Core criteria for high-quality construction techniques in maintenance

A quality maintenance process must follow strict and standardized construction techniques at every stage. This is what differentiates a quick fix from a truly sustainable solution. A competent contractor should ensure:

Image 3. Strict compliance in warehouse maintenance ensures quality control

- Accurate initial inspection: Use of advanced tools like drones, sensors, and 3D scans to assess damage.

- Well-planned execution: Precise scheduling and assigning skilled labor (welders, electricians, engineers).

- Certified materials and equipment: Prioritize materials with factory certificates, high-performance tools like laser measurers, and PU waterproofing adhesives.

- Compliance with technical procedures: Adherence to industry norms with strict supervision during execution.

- Post-construction verification: Test bonding strength, level flooring, and run electric-water systems for 7 continuous days.

These technical criteria form the backbone of effective warehouse maintenance, minimizing risks and ensuring stability over time.

4. The long-term benefits of investing in proper construction techniques

A well-executed construction plan allows early detection of potential failures and proactive intervention. Rather than opting for cheap, low-quality services, investing in advanced construction techniques brings key advantages:

Image 4. Proper warehouse repair using standard construction techniques enhances durability, reduces costs, and improves operational efficiency

- Prolong warehouse lifespan by 20–30% through thorough damage handling.

- Reduce recurring repair costs and prevent production delays due to rework.

- Enhance safety by reducing risks of electric fires, roof collapse, or structural failures.

- Ensure long-term operational efficiency, giving business owners peace of mind.

5. US Buildings – Trusted partner in warehouse maintenance

With extensive experience in warehouse repair, US Buildings is a top choice for enterprises in Southern Vietnam. Our full-package warehouse maintenance service is distinguished by:

Image 5. Schedule fixing a leaky metal roof before the rainy season arrives

- A highly skilled team of engineers and workers trained in standardized construction techniques.

- Expertise in fixing a leaky metal roof, from roof panel replacement and gutter reinforcement to anti-rust and waterproof coating — delivering total solutions for rainy seasons.

- Free consultation on technical execution before construction, helping clients plan warehouse maintenance efficiently based on their budget and optimal timing.

Construction techniques are more than technical details — they are the foundation of long-term quality and performance. Businesses that recognize this can make smart investments that save money today and build durability for tomorrow.

Image 6. Construction works should undergo regular warehouse maintenance once put into operation

US Buildings is committed to delivering professional service, cost-effective solutions, and dedicated support. We’re ready to serve warehouses in Binh Duong, Dong Nai, Ho Chi Minh City, and surrounding key industrial zones.

Contact us at 0976 795 951 or leave your information HERE to get a 10% discount and schedule a free site survey with our experts!