SYNTHESIZING INFORMATION FROM A TO Z ABOUT STEEL PREFAB BUILDINGS

Pre-engineered steel frame buildings have been and are being widely applied in many fields worldwide. However, only some fully understand the development process and the growth potential of steel prefab buildings in the future. Let's gain a deeper understanding of this type of steel frame construction with US Buildings through the article below.

1. The developmental origin of steel prefab buildings

1793: The rudimentary form of prefabricated steel structures was developed in the United Kingdom in the form of metal bars wrapped around wooden beams to reduce the risk of fire.

1797 - 1879: Pre-engineered steel frame buildings were replicated and became widely popular across the United Kingdom, with various scales and types of designs.

1891: The first prefabricated steel structure appeared and was applied throughout the United States. Many large buildings in city centers and industrial areas were constructed using pre-engineered steel frames.

1900 - Present: Steel prefab buildings have become popular and are used in various fields worldwide.

US Buildings is always ready to offer steel prefab buildings solutions worldwide.

2. Prefabricated Steel Structure

In general, most steel prefab building projects consist of three main parts. Each part includes related accessories and corresponding parameters to create a complete project. Specifically, these parts include:

2.1 Main Structure

This is the steel framework that bears the primary load of the whole pre-engineered steel frame buildings. To fulfill this function, the system includes components such as foundations, foundation beams, composite columns, trusses, beams, purlins, wind-resistant frames, and bracing systems. These components ensure the connectivity and stability of the entire steel prefab buildings project.

2.2 Secondary Structure

The steel structure includes components such as partition walls, partition wall support frames, various types of flooring, staircases, and purlins.

2.3 Cover Structure and Accessories

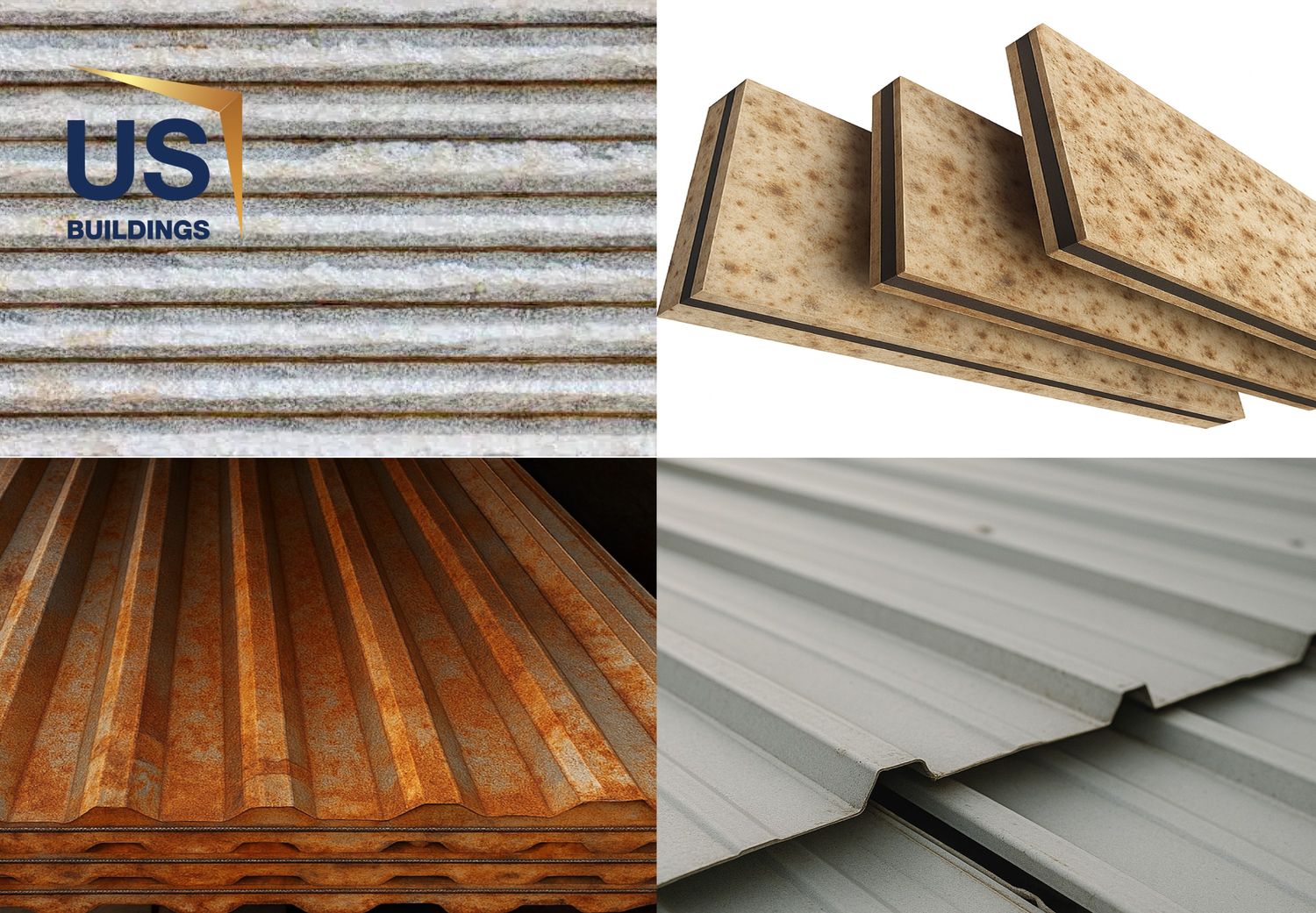

This structure plays a crucial role in completing the steel frame construction and protecting the project from external environmental factors. To perform these functions, this structure includes materials such as partition walls, roofing sheets, and cladding panels.

Prefabricated steel structure constructed by US Buildings

3. Overview of Pre-engineered Steel Frame Construction

Most high-quality steel prefab buildings are constructed through the following crucial stages:

3.1 Consult

The consultation process between the client and the investor helps both parties clearly define the requirements and business direction for the project. From there, they can develop a suitable plan for steel frame construction that meets time and cost requirements, and ensures efficiency in space and production processes.

3.2 Design

Based on the agreed-upon requirements for prefabricated steel structure from the consultation phase, the next step is to develop ideas and create technical drawings. During this stage, engineers will conduct a detailed analysis of factors such as terrain, climate, building regulations, project functions, production processes, and the accessibility of personnel, machinery, and equipment. This analysis will lead to adjustments and modifications tailored to each specific steel prefab buildings project.

3.3 Fabrication

To ensure the steel frame construction process meets quality standards, the process typically undergoes a strict production procedure involving 6-7 main steps:

-

Checking materials

-

Marking and cutting

-

Drilling and punching

-

Fitting and building up

-

Welding

-

Blasting and Painting

-

Finishing

3.4 Shipping

Depending on the area of each project, there will be different transportation methods and terms. For each steel prefab building, the customer and contractor will agree on an appropriate transportation plan and vehicle. In which, transportation by road, sea, and air are the three modes of transportation chosen by many businesses and customers for goods delivery. This helps optimize costs, minimize risks, and clearly define the responsibilities of the involved parties.

3.5 Erection

Once the prefabricated steel structures are successfully transported to the construction site, the unloading, inventory, and erection are carried out under the careful supervision of experienced engineers. Key stages to pay attention to in this step include:

- Unloading and inventorying the quantity and quality of steel components

- Installing necessary safety equipment and proceeding with erection

- Inspecting the steel prefab buildings project after the completion of construction

3.6 Warranty

With a warranty period of up to 20 years for structural design, 3 years for water leakage cases, and 3 years for accompanying materials, US Buildings confidently ensures that prefabricated steel structures remain safe and durable over time.

US Buildings brings a package solution for your pre-engineered steel buildings investment.

4. The Common Applications of Pre-engineered Steel Frame Buildings

With outstanding advantages such as short steel frame construction time, cost savings, optimized space usage, flexible design adjustments, and high reusability, steel prefab buildings are increasingly being widely used in various fields. Below are the main fields where this type is widely applied:

4.1 Agriculture

Warehouses for agricultural products, fertilizers and animal feed, livestock and poultry farms, greenhouses for cultivation, etc.

4.2 Industry

Manufacturing plants, warehouses for goods storage, processing plants, energy plants, cold storage facilities, assembly plants, etc.

4.3 Commerce

Shopping and service centers, restaurants, cafes, cinemas, showrooms and shops, warehouses and distribution centers, offices and administrative centers, exhibition and fair centers, markets and various trading areas, etc.

4.4 Public Works

Schools, hospitals, airports, airplane hangars, train stations, stadiums, garages and parking lots, laboratories, museums, churches, etc.

US Buildings constructs steel prefab buildings in multi-scale and multi-field

5. Choose a Contractor Provide Steel Prefab Buildings Solutions

The strong development of modern society has led to increased demand for public construction, residential buildings, industrial facilities, and various commercial and service projects. This helps pre-engineered steel frame buildings have become a preferred choice for many investors due to their numerous outstanding advantages.

As a company with nearly 10 years of experience in pre-engineered steel frame construction, US Buildings is proud of a highly experienced team that has completed over 250 large-scale projects worldwide. Therefore, we thoroughly analyze all your construction requirements and business directions, providing optimal solutions tailored to your steel prefab buildings.

Contact US Buildings now to explore the development potential for your steel prefab buildings project.