Why factory renovation is vital for a deteriorating factory?

Deteriorating factories can create many risks for businesses. US Buildings will help you spot signs and avoid costly damage with timely factory renovation.

1. Why is it necessary to renovate a deteriorated factory?

In manufacturing, a factory is not just a place to house equipment and operate machinery — it’s also the main working space for workers, engineers, and operations teams.

However, after years of use without regular renovation, factors like weather, humidity, heavy loads, and constant production activity can cause serious damage to the building.

Image 1. Many businesses neglect factory renovation

When a factory becomes severely damaged, the entire production process can be disrupted or exposed to major risks. That’s why renovating a factory should be seen as a long-term investment strategy, not just a reaction to emergencies.

Beyond technical factors, factory renovation also helps elevate the company's image, ensure safety, and meet standards for participating in increasingly stringent international supply chains.

2. Signs your factory needs immediate renovation

Many business owners hesitate to renovate due to concerns about cost and downtime. However, delaying repairs often leads to greater expenses down the line.

A timely factory renovation not only extends the facility’s life but also minimizes disruption by preventing sudden breakdowns. It’s a proactive step that ultimately saves more than it costs.

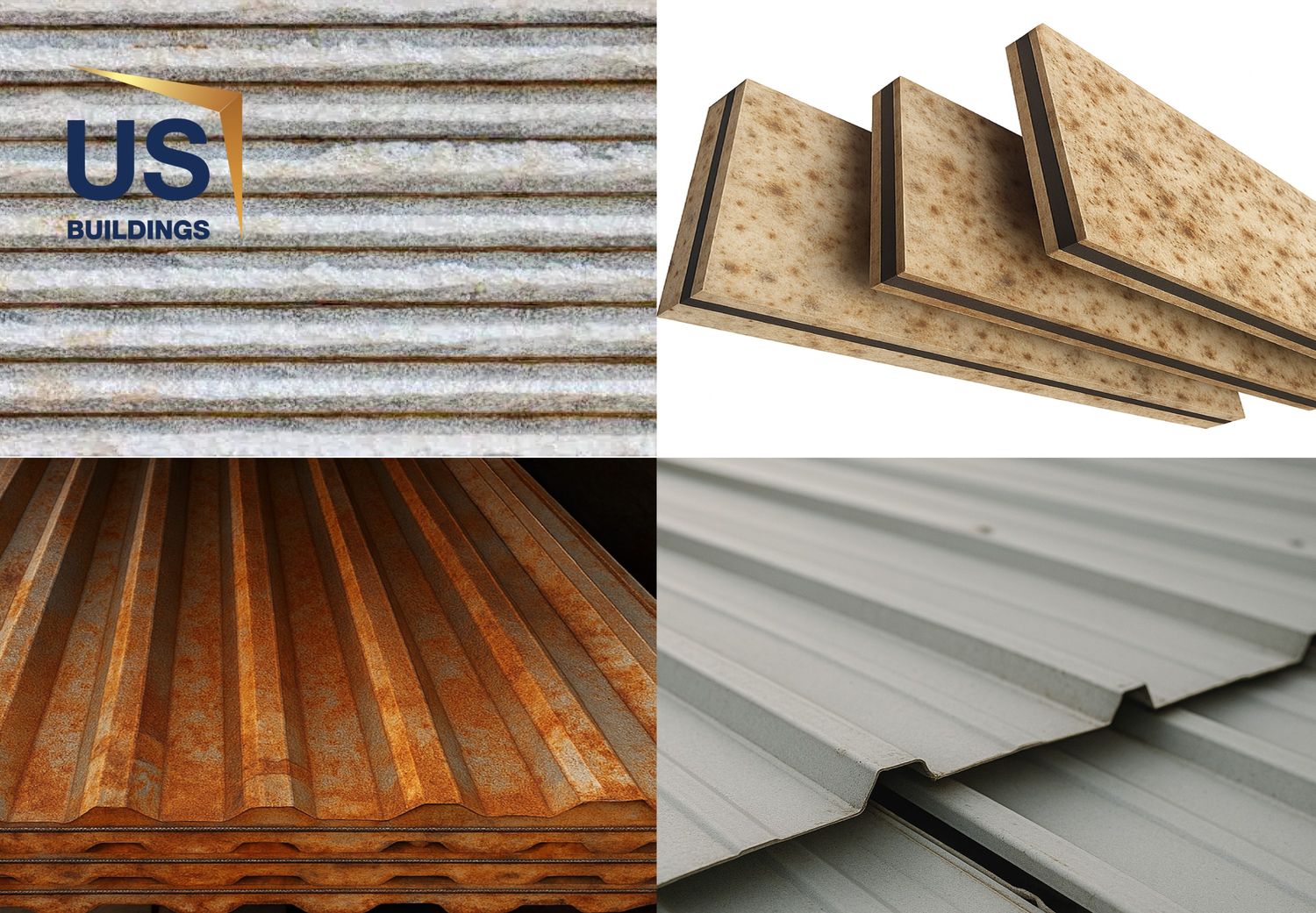

Early detection of signs of degradation will help businesses proactively implement timely factory renovation, avoiding significant losses and thereby saving considerable time, costs, and resources later on. Below are common signs indicating that your factory needs immediate renovation:

- Steel structure rusted, purlins bent: Reduces the durability and load-bearing capacity of the roof.

- Roof leaks, walls damp: Easily causes mold, damage to materials, and affects storage quality.

- Unstable electrical and plumbing systems: Leads to fires, explosions, or production interruptions.

- Floors peeling, slippery, or cracked: Creates safety hazards when moving, especially with forklifts and heavy goods.

Image 2. Signs of a deteriorated factory

Recognizing the potential for escalating damage, businesses that identify any of the aforementioned deteriorating conditions within their factory infrastructure should promptly explore comprehensive factory renovation solutions to proactively mitigate the risk of increasingly severe operational disruptions, structural failures, and economic loss.

3. How a deteriorated factory impacts productivity

Productivity relies not just on advanced technology and skilled personnel, but fundamentally on a sound infrastructure, with the condition of the facility being a particularly critical element for smooth workflows and optimal performance.

Delayed repairs can lead to costly breakdowns and production downtime. A well-maintained facility ensures smoother operations and reduces risks of accidents. Regular maintenance also helps extend the lifespan of machinery, providing long-term savings.

Without regular factory renovation, deterioration becomes a major obstacle, negatively affecting everything from machinery operation to employee morale:

- Equipment instability: Damaged foundations causing uneven support or roofing problems allowing water intrusion are common reasons for equipment instability.

- Substandard working conditions: Heat, dust, poor lighting affect health and productivity.

- Frequent technical failures: Water leaks, electrical shorts interrupt workflow.

- High small-scale factory maintenance costs: Costly but ineffective long-term.

Image 3. Deteriorated factory reduce productivity

As a result, many companies choose a full factory renovation service instead of patchwork repairs, aiming to improve operational efficiency and create a safer, more positive work environment.

A factory renovation isn’t just about fixing what’s broken - it’s also about improving layout and efficiency. Modernizing floor plans, reorganizing production lines, or integrating smart storage solutions can drastically improve workflow. The result is faster output and better resource utilization across departments.

4. Occupational safety risks from old factories

Beyond productivity, workplace safety is a top priority. A deteriorated factory that hasn’t undergone factory renovation poses serious risks of workplace accidents, leading to human, legal, and reputational consequences:

- Slippery, uneven floors: A major cause of operational accidents.

- Collapsing ceilings or walls: Especially dangerous during harsh weather.

- Electrical short-circuits: Common in aged systems.

- Hazardous working environments: Cause occupational diseases and lower labor quality.

Unrenovated factories often lack proper ventilation, lighting, and safety signage, creating an environment where small hazards can escalate quickly. These risks not only endanger employees but can also bring entire operations to a standstill.

In many cases, workers in deteriorated factories experience chronic health issues due to prolonged exposure to dust, mold, or industrial fumes. This leads to higher absenteeism, lower morale, and even long-term compensation claims.

By proactively renovating and maintaining safety standards, businesses can protect their workforce and foster a culture of care and accountability.

Image 4. Safety hazards in deteriorated factories

A proper factory renovation is not just for efficiency - it’s a critical step in accident prevention and compliance with labor laws.

5. Beyond operations: legal & brand Impacts

A damaged factory doesn’t just disrupt production - it also harms your company’s brand and legal standing.

Not doing a factory renovation can lead to workplace accidents, causing unpredictable legal consequences. The company's reputation also suffers in the eyes of customers and partners.

Failure to meet safety and quality standards can cause the business to lose opportunities to participate in major supply chains or face administrative penalties:

- A dirty, outdated, unsafe factory lowers customer and partner confidence.

- It's very hard to keep experienced and skilled workers in a run-down factory, especially if the work environment feels unprofessional and dangerous.

- Your business can miss out on opportunities to bid on projects, export goods, or work with international partners if you don't meet safety and environmental inspection standards.

- A run-down factory might be inspected and fined by government agencies if accidents happen or if it doesn't meet operating requirements.

Image 5. Legal and compliance issues in deteriorated factories

Therefore, factory renovation is more than a technical solution - it’s a vital strategy to protect your brand, stay compliant, and build trust with partners, clients, and employees.

6. US Buildings - Your professional factory renovation partner for your business.

US Buildings is always ready to work with you – from giving advice to doing the repairs – with cost-saving, effective renovation solutions that fit your specific production setup. Let US Buildings be your partner in upgrading and protecting your production facilities as the rainy season arrives.

At US Buildings, we understand that one size doesn’t fit all. Our renovation solutions are carefully customized based on your industry, environment, and operational needs.

With years of experience in steel industrial construction, US Buildings delivers comprehensive, efficient, and budget-friendly.

US Buildings’s Factory Renovation Services include:

- Replacement of insulated and heat-resistant roofing sheets.

- Epoxy floor and wall painting for durability and aesthetics.

- Steel structure reinforcement (purlins, columns, trusses).

- Waterproofing of roofs, wall bases, and foundations.

- Full factory repair service process: Inspection - Quotation - Repair - Warranty.

US Buildings provides transparent quotations and flexible scheduling to ensure minimal business disruption. We work closely with you from site survey to execution, adjusting the plan as needed. This client-centric approach ensures no hidden fees and no delays - just clear communication and reliable delivery.

We also offer scheduled factory maintenance to help clients detect issues early, reduce risks, and extend facility lifespan.

To guarantee the highest standards of quality and safety, and to ensure projects are completed within the agreed-upon timelines, all our projects are meticulously supervised by our team of highly skilled and experienced engineers who bring their extensive technical knowledge and rigorous attention to detail to every stage of the process.

Most importantly, US Buildings commits to optimizing factory repair cost - delivering solutions that suit your budget while ensuring long-term efficiency. Hundreds of businesses have trusted US Buildings to upgrade their industrial infrastructure.

Image 6. US Buildings’ professional factory renovation services

Contact us now via our hotline 0976 795 951 for a completely FREE consultation and inspection, or leave your information right HERE!