Quality of materials — The key to long-lasting industrial factories

High-quality maintenance materials ensure factories run safely, efficiently, and sustainably. This article highlights their importance, selection criteria, and long-term benefits.

1. Why is maintenance material quality so crucial for industrial facilities?

Factory maintenance is more than just fixing what’s broken. It’s a proactive, preventive process that ensures structural integrity, operational continuity, and safety. Just like how regular check-ups keep a human body healthy, factory repair keeps production environments resilient and efficient.

In this process, maintenance material types act as the first line of defense, shielding essential components from wear and deterioration. These components include roofing sheets, steel frames, anti-corrosion coatings, drainage systems, rolling doors, and gutters.

Imagine a factory located in a coastal area—without rust-resistant materials, the entire structure could deteriorate within years due to high salinity in the air. Or a production line operating in a hot climate—without proper insulation and reflective roofs, the internal temperature can rise significantly, affecting both machines and workers. This is where quality truly matters.

High-quality materials extend the lifespan of key systems, reduce maintenance frequency, and prevent costly production interruptions, all while ensuring safety for workers and protection for valuable machinery and goods.

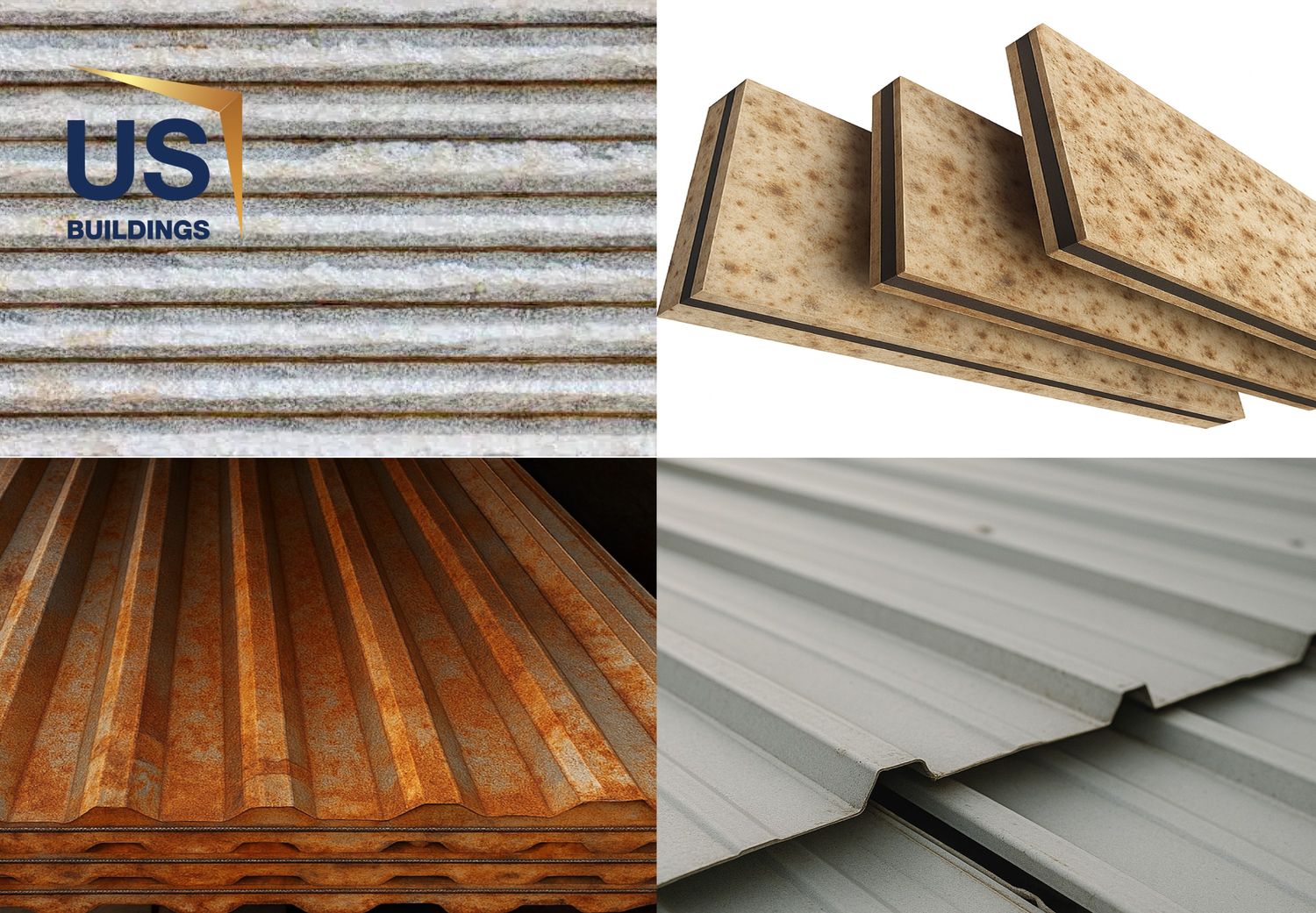

Image 1. The quality of maintenance material directly affects the life and safety of the factory

2. The risks of using low-quality maintenance materials

Many businesses attempt to cut costs by using less expensive materials during maintenance. Unfortunately, this strategy often backfires, leading to increased costs and severe operational issues. Here are the most common risks:

- Accelerated degradation: Low-quality anti-rust coatings, thin steel components, or subpar sealants quickly fail when exposed to harsh environments, leading to rust, cracks, leaks, and even structural collapse.

- Safety hazards: Water leaks from broken roof sheets or failed sealing can drip into production zones, damaging equipment or creating slippery surfaces. Poor-quality doors or supports can collapse, putting workers at serious risk.

- Rising costs: What seems like an initial saving quickly turns into a recurring expense. Low-grade materials often require frequent replacements, leading to double or triple the maintenance cost in the long run.

- Asset depreciation: A poorly maintained facility shows visible signs of wear, reducing its appraisal value. This makes it harder to sell, lease, or use as collateral for loans or investments.

- Reputational damage: In B2B environments, the physical condition of your factory speaks volumes about your standards. A rundown facility can hurt client confidence and partnership opportunities.

Image 2. Using poor-quality material types can easily cause leaks, corrosion, damage, and unsafe working conditions

3. Key criteria for choosing high-quality maintenance materials

To ensure long-term durability, selecting the right materials must follow clear technical and practical criteria:

- Clear origin and certification: Always opt for branded, certified products that comply with local and international construction standards. These typically come with documentation and testing reports from third-party labs.

- Environmental compatibility: Consider your factory’s location and operating conditions. In humid climates, prioritize anti-mold, waterproof materials. Near coastal areas, use corrosion-resistant steel or coatings. In hot zones, focus on heat-reflective roofs.

- Performance and durability: Choose products with high material strength. Look beyond appearance and ask for data—how long can this material withstand UV exposure? What’s the tensile strength of this bolt? What is the adhesion rating of this epoxy paint?

- Manufacturer and warranty: Trusted suppliers not only provide product guarantees but also technical support. This gives you legal and practical assurance if issues arise.

- Contractor recommendation: Experienced engineers or maintenance teams can provide valuable insights. They know what materials have performed well in similar projects and can guide your decision based on real-world data.

- Lifecycle cost efficiency: Always balance initial investment with long-term value. Spending slightly more upfront on quality may result in far lower costs over the building’s lifespan.

Image 3. Select factory maintenance materials with a clear origin, suitable for the environment, and quality-tested

4. The benefits of investing in premium maintenance materials

Using premium materials doesn’t just reduce problems—it creates a cycle of positive returns for your facility and business:

- Extended building life: High-performance materials protect the structure from moisture, UV rays, mechanical stress, and chemical exposure. This slows down aging and keeps systems functional for longer.

- Operational efficiency: Less downtime means more productivity. Reliable materials ensure your operations run smoothly with fewer interruptions.

- Lower total cost of ownership (TCO): Fewer repairs, replacements, and emergency interventions mean less money spent over time, even if the initial material cost was higher.

- Enhanced safety and compliance: Fewer incidents related to structural failures or leaks mean a safer environment for workers and a reduced risk of legal or regulatory penalties.

- Brand and asset value: A well-maintained, visually solid factory sends a strong signal to clients, partners, and investors about your business credibility and long-term vision.

Image 4. Good materials help the factory to be durable and beautiful, reduce repair costs, and ensure operational safety

5. Essential maintenance materials that require quality assurance

Below are some types of materials that are frequently used in factory renovation construction and require special attention to quality:

- Anti-rust paint & epoxy coatings: These protect steel structures and concrete surfaces from corrosion and environmental damage. Make sure the paint system you use has high adhesion and is tested for resistance to chemicals, humidity, and UV.

- Roofing sheets, gutters & skylight panels: These are constantly exposed to the weather. Choose materials that are UV-resistant, impact-resistant, and do not become brittle over time.

- Sealants and waterproof fillers: Used at connection joints and seams, especially in roofs and piping systems. Their elasticity, bonding strength, and weather resistance are crucial.

- Lightning protection and MEP components: Electrical systems must comply with strict safety regulations. Use certified grounding systems, rustproof conduits, and industrial-grade insulation.

- Bolts, nuts, fasteners: Often overlooked, but fasteners hold everything together. Use galvanized or stainless-steel options with verified load capacity and corrosion resistance.

Neglecting quality in any of these can compromise the entire facility.

Image 5. Roofing sheets, gutters, and skylights are products that require strict quality control to ensure material strength

6. US Buildings – Reliable factory maintenance services with certified materials

With over 10 years of industry experience, US Buildings has become a trusted partner in designing, constructing, and maintaining industrial buildings across Vietnam and Southeast Asia.

We are committed to:

Using only high-quality, certified materials from trusted suppliers.

- Offering free on-site inspections and technical consultations tailored to your building's condition and your business needs.

- Deploying professional engineers and technicians to ensure safety, technical precision, and timely execution.

- Providing long-term warranties and after-service support with quick, responsive care.

We understand that quality is not a cost—it’s an investment in the safety, sustainability, and success of your business.

Image 6. US Buildings commits to a free survey and factory renovation construction with high-quality products

Need maintenance support or material consultation for your factory? Contact US Buildings at 0976 795 951 or leave your information HERE to schedule a free inspection and receive a tailored proposal.