Quality inspection process ensures factory safety

The process of quality inspection for factory constructions is crucial for ensuring safety, efficiency, and legal compliance from design to construction and operation.

1. What is factory construction quality inspection?

Quality inspection is an objective assessment activity to confirm the conformity of a construction with technical standards and regulations in building.

This is an important process that helps investors, contractors, and related parties understand the status of the construction, ensuring all elements meet requirements before being put into operation.

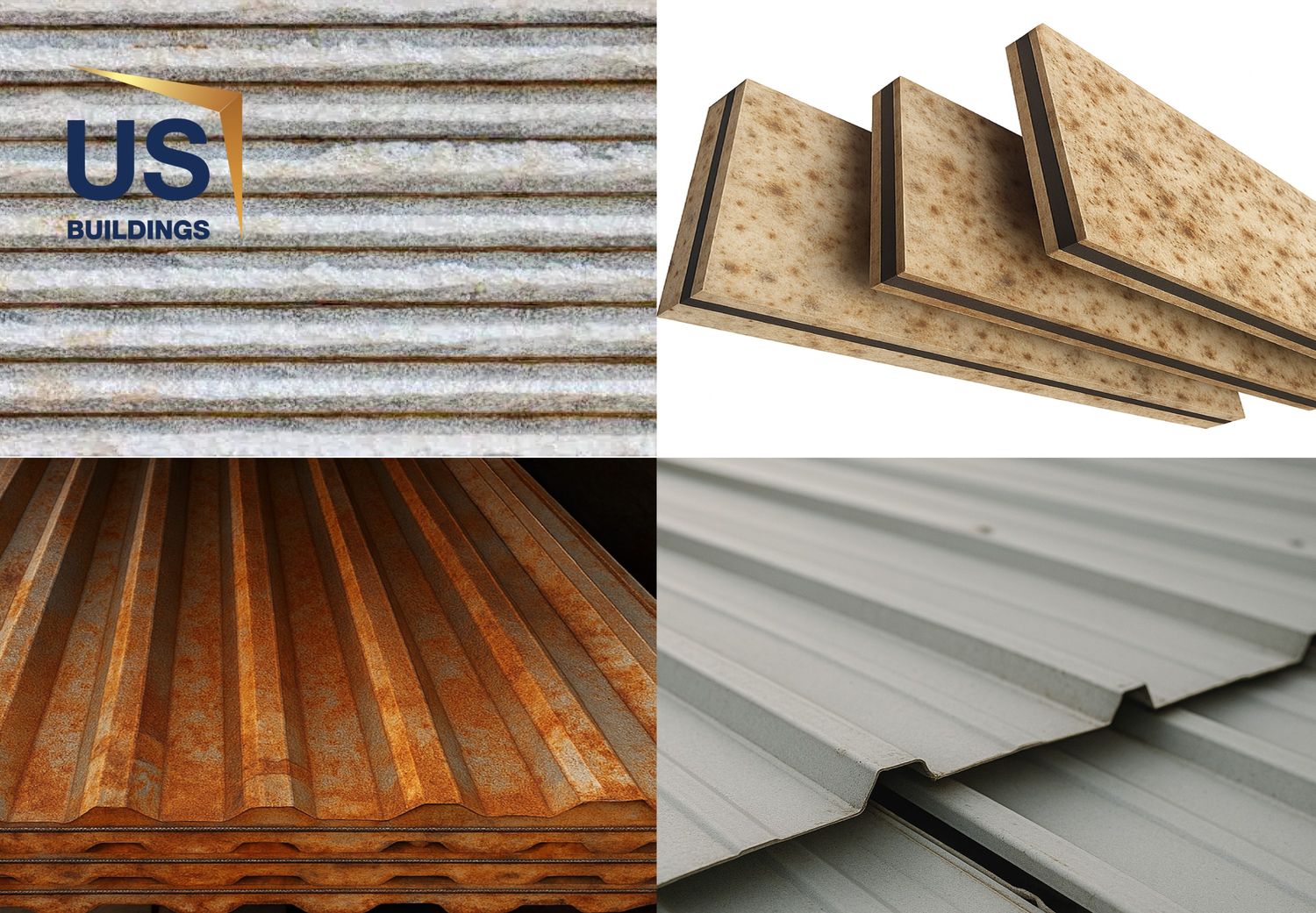

Image 1. Strict inspection process

An effective inspection process helps detect early technical, material, or structural issues. From there, adjustments or timely remedies can be made, reducing future repair costs and avoiding serious incidents affecting worker safety and property.

2. When is quality inspection needed?

Inspection is not a one-time event but should occur throughout the lifecycle of the construction.

The process includes:

- Design phase: Evaluating the rationality, safety of structural drawings, proposed materials, bearing capacity, etc.

- Construction phase: Monitoring progress, construction quality, accuracy in implementing drawings, using approved materials.

- Completion phase: Acceptance of the construction, overall assessment, and licensing for operation.

- Operation phase: Periodic inspection to ensure the structure does not deteriorate, especially after natural disasters, incidents, or as required by law.

Image 2. Team conducting factory maintenance

Depending on the type of construction, scale, and function, the timing and content of inspections can be flexibly adjusted. However, to ensure accuracy and legal validity, adhering to a specific process is indispensable.

3. Factory construction quality inspection process

A comprehensive and scientific factory quality inspection process typically includes the following steps:

Step 1: Receiving documents and on-site survey

Before proceeding with inspection, the performing unit will receive documents related to the construction such as:

- Technical design drawings.

- Legal documents (construction permits, construction contracts, etc.).

- Construction log, acceptance records for each item.

- Material testing results (if any).

Then, they will conduct an on-site survey of the construction to grasp its scale, current status, and identify areas requiring in-depth inspection.

Image 3. Supervising steel frame factory construction process

Step 2: Developing an inspection plan

Based on the survey results, the inspection unit develops a specific plan including:

- Scope and content of inspection.

- Required equipment and tools.

- Personnel involved.

- Implementation timeline.

- Applicable standards and regulations.

Before implementation, the entire plan will be submitted to the investor for review and approval to ensure consistency and effectiveness for the project.

Step 3: On-site inspection

This is a key step in the inspection process. Engineers and specialists will perform:

- Measuring settlement, tilt, deflection of the construction.

- Testing materials, load-bearing structures.

- Checking technical systems (electricity, water, fire protection, etc.).

- Comparing actual construction with design documents. All activities during the implementation process are fully and detailedly recorded, accompanied by actual images and specific technical parameters, to ensure transparency and serve as clear evidence for each stage.

Step 4: Analyzing and evaluating results

After completing the inspection according to the process, data will be aggregated and analyzed according to technical standards. The purpose is to determine:

- Whether the construction meets safety and quality requirements.

- Which areas show deviations, damage, or potential risks.

- Necessary corrective or improvement measures. From this, the construction supervision and inspection unit provides a detailed report and specific recommendations to the investor.

Step 5: Preparing and handing over the inspection report

The quality inspection report includes:

- General information about the construction.

- Description of the inspection process performed.

- Images and results of measurements, tests.

- Findings and conclusions. This serves as the basis for completion, operation, or requiring repairs before the construction is officially put into use.

4. Factors affecting inspection effectiveness

For an inspection process to achieve maximum effectiveness, the following factors should be emphasized:

- Document quality: Complete and accurate documents help the inspection process be faster and more transparent.

- Professional competence: The inspection unit must have a team of experienced, licensed, and clearly qualified engineers and specialists.

- Equipment, technology: The application of modern measuring equipment such as strain gauges, concrete ultrasonic machines, etc., helps achieve accurate results and reduce errors.

- Coordination among parties: Investors, contractors, supervision units, and inspection units need to work closely to ensure objectivity and effectiveness.

5. Role of construction process and supervision in inspection

In the overall inspection process, two elements play a particularly important role: construction process and construction supervision. If construction is technically sound, adheres to drawings, and is tightly supervised, subsequent inspection will be much easier.

Image 4. Always inspect construction quality inspection at each stage

A standardized construction process from foundation pouring, steel frame erection, roofing, interior finishing... helps control the quality of each stage. In particular, supervision helps ensure every step of construction complies with regulations and detects errors promptly.

6. Maintenance and periodic inspection ensure safe factory operation

Even if the construction is completed and put into use, the inspection should not end. Many businesses overlook regular factory maintenance, leading to silent damage accumulation and serious consequences later. Periodic factory maintenance combined with re inspection every 3-5 years will help you:

- Extend structural lifespan.

- Early detection of weaknesses and cracks.

- Ensure safety in harsh weather conditions.

- Optimize repair costs. This is part of an effective and sustainable industrial asset management strategy.

7. Ensuring construction quality with US Buildings

A factory construction not only needs to be built on schedule, according to process, and design, but also needs to ensure absolute quality to meet the demands of production, storage, or industrial operation.

Image 5. Project completed on schedule due to construction supervision

Building and rigorously implementing a thorough quality inspection process is a "technical barrier" that helps protect a significant investment for businesses.

With many years of industry experience and a team of highly skilled engineers, US Buildings is committed to accompanying businesses from the first drawing until the construction is operational, ensuring compliance with technical standards – on schedule – and optimizing costs for customers.

Contact US Buildings now via hotline: 0976 795 951 or leave your information HERE for prompt support!