Which maintenance approach helps optimize factory repair expense?

Understanding the differences in factory repair expense between periodic maintenance and breakdown maintenance helps businesses choose the right approach to optimize expenses.

1. Factors affecting factory repair expense

Factory repair expense is always a top concern for manufacturing businesses. Choosing the right maintenance method not only helps reduce operating costs but also extends the building's lifespan and ensures workplace safety.

Below are some key factors that can impact the cost of factory repair:

- Factory condition: The current state of the factory is the first factor influencing the factory repair expense. A factory with multiple damaged areas will require a higher repair cost compared to one that undergoes regular maintenance and inspections.

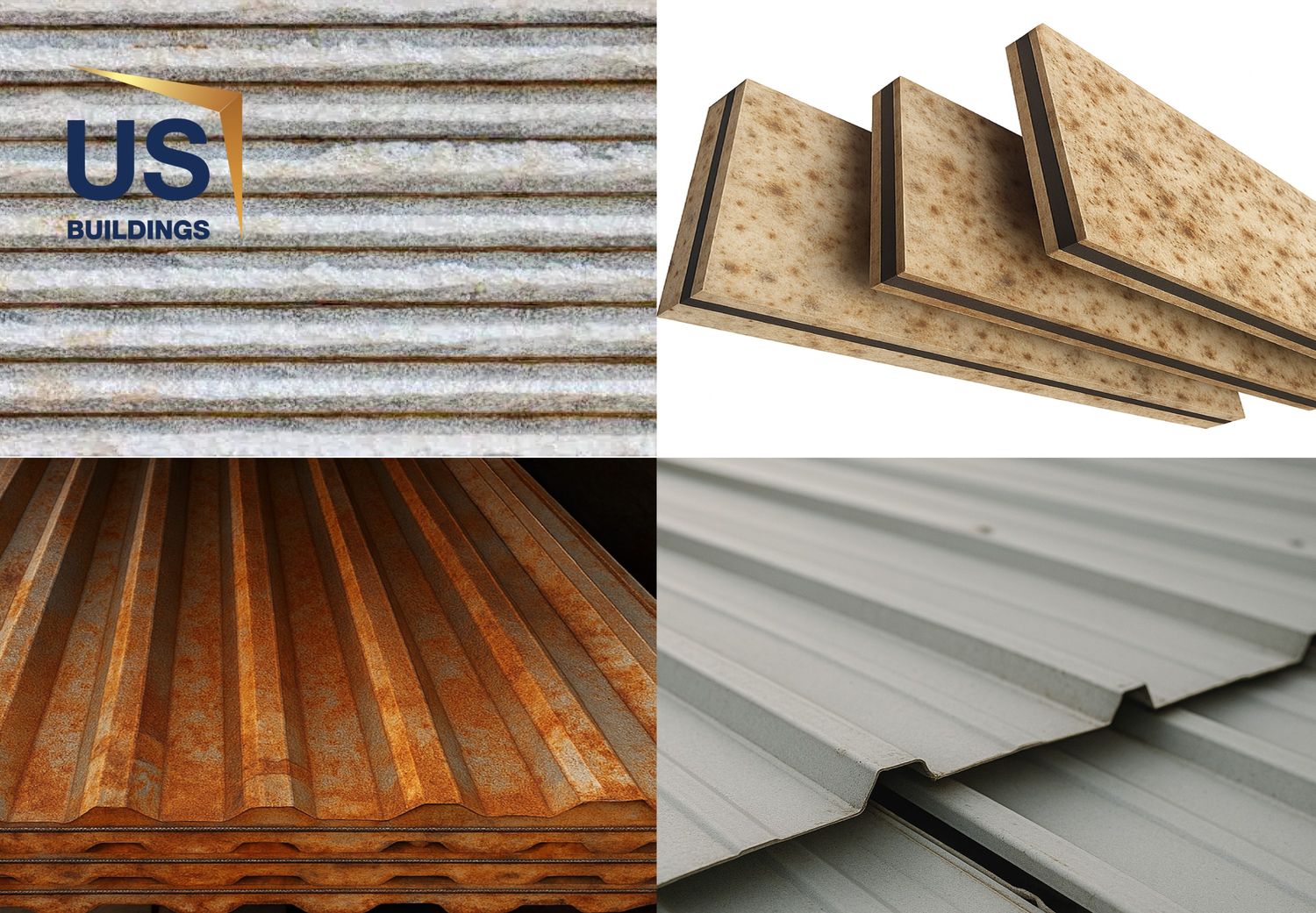

Image 1. Maintenance approach is one of the key factors affecting factory repair expense

- Applied maintenance approach: The type of maintenance a business chooses also significantly impacts the factory repair expense. Therefore, businesses that opt for periodic maintenance often have better long-term cost control.

- Construction time: Project timeline is also a crucial factor. If a business requires urgent repair work in a short timeframe, the factory repair expense will be higher compared to having a planned and fixed maintenance schedule.

2. Impact of maintenance approach on factory repair expense

Among the various factors influencing factory repair expense, the maintenance approach that a business adopts is a key element in determining the effectiveness of its investment budget.

There are two common types of maintenance including periodic maintenance and breakdown maintenance.

Image 2. Choosing the right maintenance approach helps businesses optimize factory maintenance cost

- Periodic maintenance: This type of maintenance is typically planned in advance on a quarterly or yearly basis. As a result, businesses can easily allocate budgets for each item. In most cases, the factory repair expense remains reasonable and does not fluctuate unexpectedly.

- Breakdown maintenance: In contrast to periodic maintenance, this is a reactive approach, where businesses only carry out urgent repairs when major damage occurs. This is also the reason why the factory repair expense in this case often spikes uncontrollably.

Therefore, choosing the right maintenance approach brings long-term stability to factory repair expense. Understanding the differences between maintenance options clearly is also a critical foundation for businesses to develop efficient and cost-effective operational strategy.

3. Periodic maintenance and breakdown maintenance: Comparing their impact on factory repair expense

To clearly understand how each approach affects factory repair expense, it is essential to compare periodic maintenance and breakdown maintenance across several aspects such as unexpected costs, level of control, and long-term impact on production.

- Unexpected costs: Periodic maintenance helps keep factory repair expense low by addressing small issues early, reducing the risk of major damage. In contrast, breakdown maintenance often leads to sudden, high repair costs due to uncontrolled damage.

Image 3. Periodic maintenance helps businesses effectively control long - term factory renovation cost

- Proactiveness: Periodic maintenance allows businesses to plan ahead, manage budgets, and prepare resources effectively. In contrast, breakdown maintenance is reactive, often requiring urgent factory maintenance that causes financial strain and disrupts production.

- Long-term impact: Continuously delaying repairs until problems occur worsens the factory’s condition over time. This may lead to major investments in factory renovation, with costs far exceeding those of regular periodic maintenance.

From the above comparisons, it is clear that periodic maintenance not only helps control factory repair expense, but also brings proactiveness, stability, and long-term savings, while protecting assets and supporting sustainable growth.

4. Periodic maintenance procedure helps optimize factory repair expense

Proactively planning periodic maintenance is the most effective way to ensure stable factory operations and control factory repair expense.

Instead of waiting until serious damage occurs, US Buildings will help businesses develop a professional periodic maintenance plan to prevent risks and optimize long-term expenses.

Step 1: Receiving requests and conducting on-site inspection

Customers needing periodic maintenance only need to contact us at 0976 795 951. Our technical team will promptly schedule a site survey.

We will conduct a comprehensive assessment of the factory and related areas to identify signs of wear or potential damage, factors that could increase factory repair expense if not addressed early.

Step 2: Proposing solutions and providing transparent pricing

After the inspection, US Buildings will prepare a detailed and transparent quotation for each maintenance item.

The goal is to help businesses estimate budgets in advance and avoid unnecessary extra costs. Proper control from the beginning will help stabilize factory repair expense in the long run.

Image 4. The factory maintenance procedure at US Buildings is carried out by a highly skilled technical team

Step 3: Performing maintenance according to technical standards

The maintenance process is conducted by a highly specialized team, strictly following every step in the factory maintenance procedure. Every construction detail is closely monitored to ensure durability, safety, and to prevent recurring issues.

Step 4: Project handover and clear warranty policy

Once completed, the project is inspected and officially handed over with a warranty policy of up to 365 days.

During this period, any issues will receive timely technical support, allowing businesses to operate with peace of mind, without worrying about unexpected costs related to factory repair expense.

5. Contact US Buildings for a free factory repair expense estimate

Don’t let factory deterioration affect production efficiency or lead to higher factory repair expense in the future. Understanding repair expenses in advance helps businesses stay proactive in their maintenance planning and investment decisions.

Image 5. US Buildings – A provider of periodic maintenance services with transparent factory repair expense

When choosing periodic maintenance services from US Buildings, our technical team will visit and inspect the factory on-site, and it is completely free of charge.

Especially during this June, customers will receive an attractive discount of up to 10% for factory repair and renovation services.

If you need an on-site inspection and a factory repair expense estimate, please contact us at 0976 795 951 or leave your information HERE to receive FREE support!