Why you need to replace your skylight plastic roofing for factories?

Skylight plastic roofing will degrade due to environmental and weather impacts. Therefore, it needs to be replaced promptly to maintain operational efficiency and ensure production safety.

1. Why replace factory skylight roofing?

Over time, skylight plastic roofing is often affected by harsh weather and environmental factors, leading to damage or reduced light transmission efficiency.

If not replaced promptly, businesses may face high factory maintenance costs and production disruptions. Here are reasons you should consider replacing them now:

- Save electricity costs: Skylight plastic roofing maximizes natural light, thereby minimizing the use of artificial lighting systems during the day.

- Ensure safety: Old plastic roofing sheets are prone to cracking or leaking, posing potential occupational safety risks.

- Protect machinery and goods: Prevents rainwater from seeping into production areas, limiting damage to machinery and products.

- Enhance corporate image: A bright and clean factory creates a good impression on partners and customers, demonstrating professionalism.

- Proactive factory maintenance: Timely replacement helps limit incidents, ensuring continuous production operations.

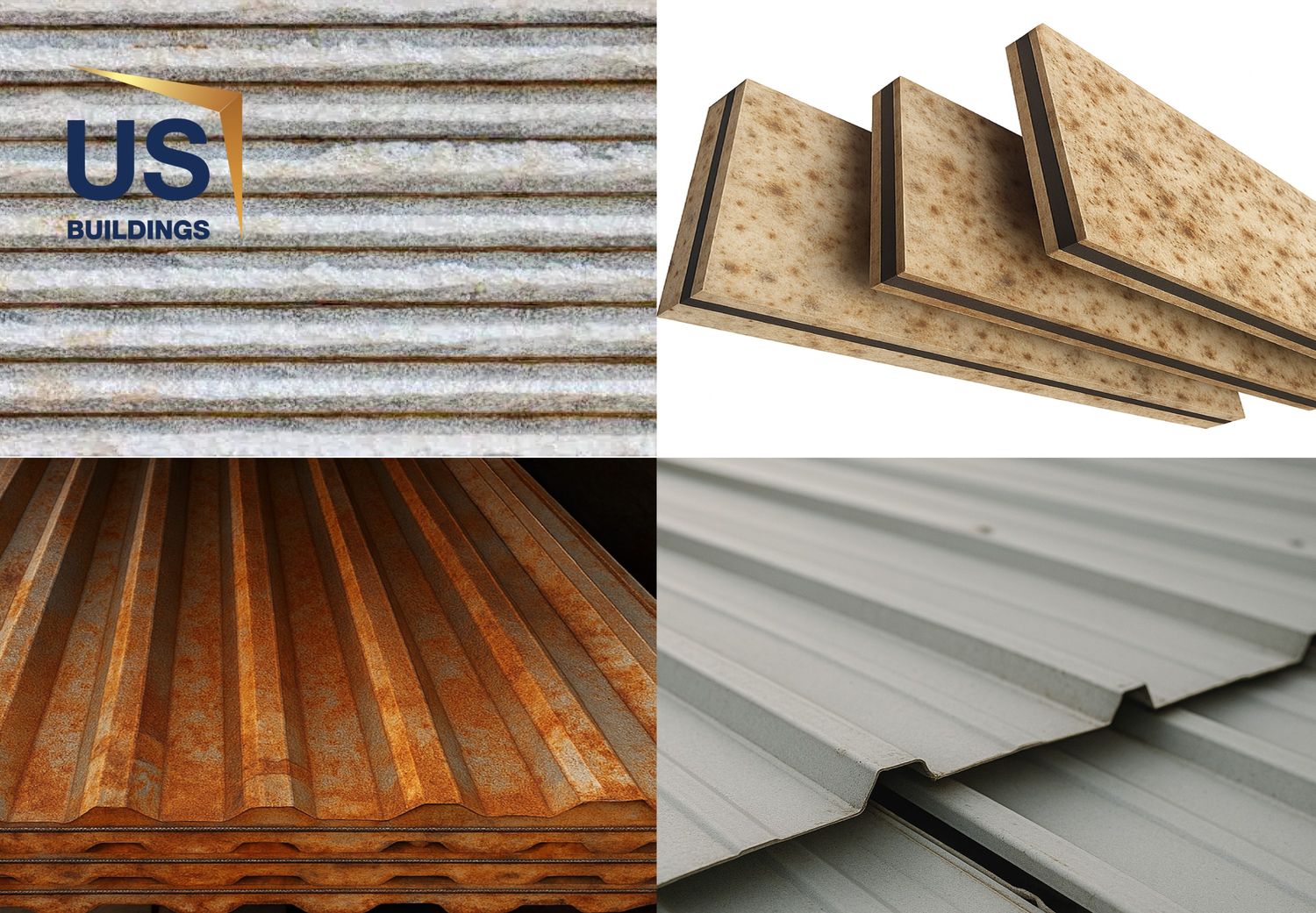

Image 1. Corrugated polycarbonate light-transmitting sheet

2. Signs that your skylight plastic roofing has degraded

Replacing skylight plastic roofing should be done as soon as signs of degradation appear to ensure the necessary amount of natural light for the factory space.

Delayed action will force the lighting system to operate continuously, increasing electricity costs and reducing equipment lifespan. Here are some warning signs to help you identify and address the issue:

- Plastic roofing sheet changes color, yellows: This is the most common sign after 3-5 years of using skylight plastic roofing, especially in areas with intense sunlight and industrial dust.

- Cracking, brittleness: Under the effects of UV rays, high temperatures, and acid rain, the plastic roofing sheet easily ages and loses its elasticity.

- Leaking during rain: Cracks or gaps at the joints between the plastic roofing sheet and metal roofing cause water leakage, severely affecting goods and machinery.

- Reduced light transmission: When there isn't enough clarity, natural light cannot penetrate, forcing the factory to increase artificial lighting.

Image 2. Hollow polycarbonate light-transmitting plastic roofing sheet

3. Harms of using old, low-quality plastic roofing sheets

Continued use of old or low-quality skylight plastic roofing can lead to serious consequences for production operations. Here are some harms businesses may face if they don't replace them promptly:

- Affects factory lighting system: Old skylight plastic roofing will reduce light transmission, causing the factory to turn on more lights during the day. This leads to faster degradation of the lighting system and increased electricity costs at the factory.

- Causes damage to equipment and goods: When the clear plastic roofing sheet leaks, rainwater can seep into the production area, damaging machinery and affecting product quality – especially in industries like electronics, textiles, and food.

Image 3. Businesses should schedule annual factory maintenance

- Does not ensure occupational safety: Cracked or broken pieces of plastic roofing sheet can fall and pose dangers to workers. Additionally, rainwater leaking onto wet floors increases the risk of slipping and falling.

4. Benefits of replacing skylight plastic roofing at the right time

Regular replacement of skylight plastic roofing is not just a solution for waterproofing, but also an effective factory maintenance strategy. Timely replacement brings many practical benefits to businesses, maintaining operational efficiency for the factory, such as:

- Optimize natural light: Modern plastic roofing sheets currently have light transmission capabilities ranging from 70% - 90%, helping to maximize daylight and significantly reduce lighting costs.

Image 4. Clear plastic roofing sheet in solid form

- Effective UV protection and heat insulation: Modern skylight plastic roofing is coated with a UV layer, which prevents heat and harmful rays from entering, contributing to cooling the factory space.

- Increase lifespan of factory roof: Compared to galvanized iron or traditional skylight panels, polycarbonate sheets have many times higher durability, good load-bearing capacity, impact resistance, oxidation resistance, and corrosion resistance.

- Easy to replace, fast installation: Replacing plastic roofing sheets does not take too much time and can be done area by area without interrupting production activities.

Replacing skylight plastic roofing not only brings economic value but also ensures long-term operation for businesses. Especially in manufacturing industries that require a stable working environment such as food, garment, and electronic components.

5. Popular types of skylight plastic roofing today

Choosing the right type of skylight plastic roofing not only ensures effective light collection but also helps extend the roof's lifespan. To optimize and save long-term factory maintenance costs, businesses can refer to the 3 most popular types of roofing today:

- Polycarbonate sheet: This is a high-grade transparent plastic, with superior durability and light transmission capabilities. This polycarbonate sheet is often used for large factories with high requirements for durability, heat insulation, and aesthetics.

- Composite plastic roofing sheet: Often made from fiberglass combined with polyester resin, it is cheaper than polycarbonate sheet but has lower durability and light transmission.

- Clear PVC plastic roofing sheet: Suitable for civil constructions, small-scale warehouses, with moderate light transmission, cheap but easily brittle after a few years of use.

6. When to replace your skylight plastic roofing?

Choosing the right time to replace skylight plastic roofing will help the roof renovation process go smoothly, avoid risks, and ensure production progress. To avoid interrupting production activities, refer to the following cases where you should consider replacing your skylight roofing as soon as possible:

- Plastic roofing sheet shows signs of fading, cracking, leaking: This is a sign that the material has degraded, no longer ensures light collection, and can easily cause water leaks, affecting production.

Image 5. Metal roof after replacement completion

- Repair costs are higher than replacement costs: Repeated repairs are costly and less effective than replacing the entire roofing system.

- Businesses need to renovate, expand, or upgrade their factory: When upgrading production space, replacing skylight plastic roofing helps ensure aesthetics, lighting, and long-term effective use.

7. Notes when choosing and replacing skylight plastic roofing

To avoid unnecessary costs, choosing the right type of skylight plastic roofing and installing it with correct techniques is extremely important. Here are some points you need to keep in mind before replacing your factory skylight roofing:

- Choose high-quality products from reputable brands with clear warranties.

- Prioritize polycarbonate sheets if you want high durability, good light transmission, and heat resistance.

- Install with correct techniques, seal joints tightly to prevent future leaks.

- Combine with regular factory maintenance and cleaning of the skylight to extend its lifespan.

Image 6. Factory skylight polycarbonate sheet – A smart and cost-effective solution

8. US Buildings - A Reliable partner in factory renovation and maintenance in the southern region

We provide comprehensive solutions for replacing skylight plastic roofing, with fast and technically sound installation, ensuring long-term effective use. We especially emphasize safety and efficiency during the construction process.

All items are strictly supervised by our experienced team of engineers. After the project is completed, customers will receive guidance on periodic factory maintenance and free technical support throughout the warranty period.

Image 7. US Buildings team specializes in professional factory roof sheet replacement

If you are looking for a reputable – fast – effective partner for this rainy season, do not hesitate to contact US Buildings immediately for a free survey and receive up to 10% off for skylight plastic roofing replacement services or factory maintenance to safely and economically welcome the rainy season.

Contact us now via phone: +84 976 795 951 or leave your information HERE to receive technical consultation from our experts and schedule a completely FREE survey!