5 signs your factory’s panel sheets need replacing fast

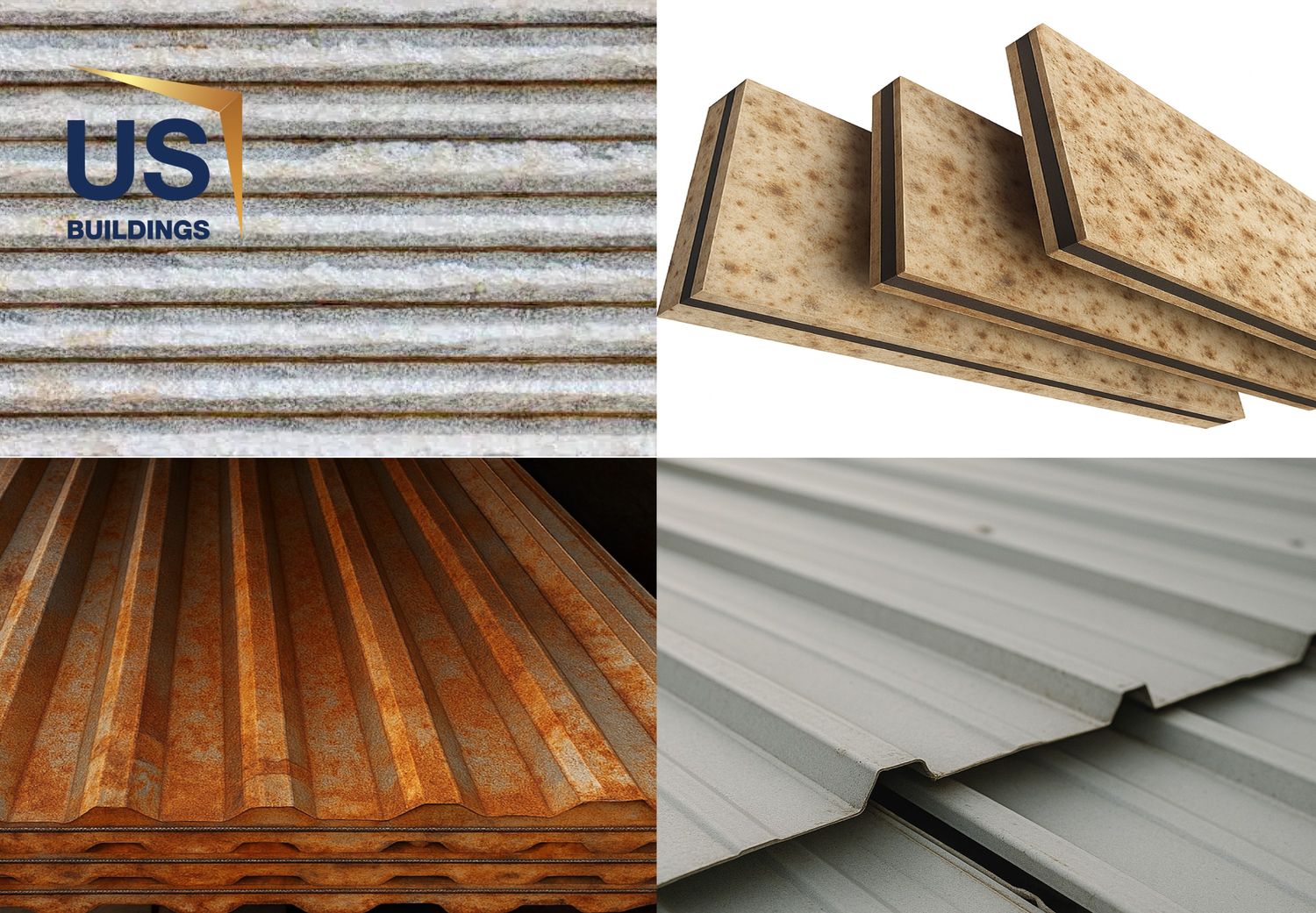

Spot 5 signs your factory’s panel sheets are damaged—act fast to avoid risks and keep thermal and acoustic performance strong for long-term efficiency.

1. Why are panel sheets important for factories and why should you detect damage early?

In the modern industrial sector, panel sheets play an essential role in factories. They help with insulation, soundproofing, and maintaining the structural integrity of the building.

When a panel sheet is damaged, not only does the insulation and soundproofing performance decline, but it also creates potential occupational safety hazards. Timely replacement helps reduce unexpected costs due to property damage or production disruption.

Image 1. Panel sheet play a crucial role in factory operation

The sturdy structure, stable performance, and durability of panel sheets are indispensable for sustainable factory operation.

2. Sign 1: Noticeable surface deformation – warping, bulging, or denting

One of the first common signs of a damaged panel sheet is visible surface deformation. Warped, bent, bulging, or dented sheets clearly indicate mechanical damage.

Deformed panel sheets no longer fit tightly, creating gaps that allow water or air to seep in. This directly affects thermal performance and ruins the overall aesthetics of the building.

Image 2. Panel sheets with surface deformation, warping, and dents

Common causes include sudden temperature changes, uneven pressure, improper installation, or low-quality materials. Once deformation is detected, replacing the panel sheet as soon as possible is highly recommended.

3. Sign 2: Declining thermal and acoustic performance

An insulated panel is the key to maintaining performance in modern factories. When insulation weakens, air conditioning must work harder, resulting in higher energy consumption.

Additionally, a soundproof panel is vital because a noisy factory environment can be uncomfortable and reduce worker health and productivity. This is a typical result of deteriorated panel sheets.

Image 3. Soundproof and insulated panel used in factory construction

Regular inspections are essential to assess the soundproofing and thermal performance of panel sheets. If current levels differ significantly from the original specs, immediate replacement is needed to avoid long-term losses.

4. Sign 3: Water leakage, mold, or stains appear

If you spot stains, mold, or discoloration on walls or ceilings, the likely cause is water ingress through the panel sheet. This is one of the most serious and visible signs of damage.

Mold, dampness, or stains on the surface indicate deterioration. It can lead to fungal growth, making the factory environment damp and affecting worker health.

Image 4. Insulated and soundproof panel showing signs of moisture, mold, and stains

This often occurs at joints, archways, or compressed areas. When the internal foam absorbs water, it loses its insulating properties and becomes a breeding ground for mold.

This not only damages assets and equipment but also negatively impacts employee health. In this case, replacing the panel sheet is urgent and non-negotiable.

5. Sign 4: Outer layer of insulated metal panel peels, fades, or rusts

Another clear sign of deterioration is when the outer layer of the insulated metal panel begins to peel, fade, or rust. This is often seen after several years of use.

Image 5. Insulated metal panel with peeling, rusting surfaces

In tropical, coastal, or rainy climates like Vietnam, panel sheets are prone to oxidation if the protective layer fails. Once the paint peels, corrosion sets in quickly.

If rust spots appear on the surface, replacement must be planned immediately. If neglected, the panel’s skin may rot, crack, or even collapse.

The deterioration of the outer shell not only affects aesthetics but compromises the entire panel sheet system. Periodic inspections and timely replacement are crucial when rust signs appear.

6. Sign 5: Loose or detached joints between panel sheets

Loose or open joints between panel sheets are a major cause of water leaks and heat loss. These areas are also vulnerable to vibration or temperature fluctuations.

When joints detach, the tight seal between panels weakens, increasing the risk of rainwater, insects, or dust infiltration. This seriously affects the factory's work environment.

Image 6. Loose and detached joints between panel sheets

You can temporarily fix this with sealants or screws, but if the issue recurs, replacing the panel sheet is a more sustainable and effective solution.

7. Consequences of not repairing damaged panel sheets in time

If not detected and replaced promptly, damaged panel sheets can lead to serious consequences. First, electricity costs spike due to the extra load on air conditioning.

The working environment becomes hazardous due to leaks, ceiling collapse, or fire risks from electrical shorts. In addition, mold and rust damage the factory’s aesthetics, affecting your brand image.

Image 7. Neglecting panel sheet repairs can severely impact business operations

Replacing panel sheets is not just repair—it’s a long-term investment in safety and sustainability. Don’t let small signs of wear lead to major problems later.

8. US Buildings – Professional factory repair and maintenance service

With years of experience in pre-engineered steel buildings and factory repair, US Buildings is the trusted partner for businesses needing panel sheet repair or replacement.

We offer a full-service solution from on-site inspection to construction and maintenance—saving time and optimizing costs.

We understand that each factory has unique operations, processes, and environments. That’s why issues such as damaged, leaky, or rusty panel sheets are carefully inspected and addressed with tailored solutions for long-term results.

US Buildings specializes in:

- Replacing insulated roof panel sheets, skylight panels, trims, and gutters to enhance heat retention and water drainage.

- Reinforcing corroded steel structures such as columns, purlins, and trusses.

- Completely solving leaks, mold, or damp panel sheets in roof, wall base, and foundation areas.

- Applying epoxy coating for floors and ceilings/walls to boost brightness, reduce dust, and improve panel sheet aesthetics.

- Upgrading ventilation and HVAC systems (heating, ventilation, and air conditioning) to reduce the load on insulated panels in high-heat environments.

- Full-scale factory repair: inspection – consultation – quotation – construction – periodic maintenance.

Our commitments at US Buildings:

- Using high-quality panel sheets that meet industrial standards with optimal insulation, soundproofing, and moisture resistance.

- Accurate construction with minimal waste and downtime, avoiding production interruptions.

- Skilled engineers and workers capable of handling everything from rusted insulated metal panels to complete roof restoration.

- Clear warranty and periodic maintenance to extend the life of panel sheets and the whole facility.

- Transparent, budget-friendly consulting to optimize costs while ensuring lasting quality for your factory.

Image 8. US Buildings – Your trusted and fast-responding partner for factory repair

US Buildings is not only a leader in pre-engineered steel building construction, but also an expert in professional, safe, and fast panel sheet renovation and factory repair.

Contact US Buildings now via hotline 0976 795 951 or leave your info HERE to get free consultation and site inspection within 24 hours!