Poor factory ventilation: Mold outbreaks in the rainy season

Poor factory ventilation in the rainy season raises humidity, triggering mold growth and negatively impacting machinery, products, and workers’ health.

1. Why is poor factory ventilation a serious issue during the rainy season?

When the rainy season arrives, humidity levels rise, causing the production areas in factories to become damp. In this condition, a poorly functioning factory ventilation system is one of the most common causes of mold outbreaks.

Inefficient factory ventilation leads to poor air circulation, trapping dust, moisture, and harmful substances inside the factory. This directly affects workers’ health and the quality of products.

Especially in industries like food processing, pharmaceuticals, or electronics, where cleanliness, dryness, and ventilation are strictly required, the factory ventilation system must be regularly inspected.

Image 1. Poor factory ventilation causes many serious consequences

Many factories have been operating for years without upgrading or renovating their factory ventilation system. As a result, after every rainy season, businesses face risks like machine breakdowns, damaged goods, and significantly reduced productivity.

Therefore, the importance of factory ventilation must not be underestimated—especially during prolonged periods of high humidity.

2. Poor ventilation creates ideal conditions for mold growth

In production environments with high humidity and poor air circulation, mold develops extremely quickly. Additionally, factories with poor airflow, limited lighting, and water seepage in the walls become an ideal environment for mold to spread.

When factory ventilation is not optimally designed, areas like wall corners, ceilings, and equipment gaps tend to retain moisture.

After several days of continuous rain, black or green mold spots begin to appear. These not only reduce aesthetics but also cause unpleasant odors, affecting the morale and health of workers.

Image 2. A poorly designed factory ventilation system causes mold

One of the causes is that the factory ventilation system is designed with the wrong capacity, without carefully accounting for seasonal factors and the specific production requirements of the business.

Moreover, installing exhaust fans without supply fans or placing fans in the wrong positions also prevents proper air circulation, creating stagnant air zones throughout the workshop.

When the factory ventilation system no longer meets actual demand, early detection and timely improvement are essential to protect the production space from mold and harmful moisture.

3. Consequences when the factory ventilation system deteriorates in the rainy season

First, inefficient factory ventilation causes machines to rust and malfunction, increasing continuous factory repair and maintenance costs. This happens because many businesses underestimate the seriousness of a degraded factory ventilation system.

Second, a humid environment directly affects product quality. In industries like textiles, food, or pharmaceuticals, high humidity can alter product integrity, damage goods, or cause returns due to not meeting quality standards.

Lastly, poor factory ventilation severely impacts worker health. Employees may develop respiratory illnesses, allergies, or skin conditions. This not only reduces productivity but also increases medical expenses and turnover rates.

Image 3. Deteriorated factory ventilation fans impact production and workers’ health

Without timely solutions, businesses might have to halt operations to address issues, causing major losses in revenue and reputation.

4. Signs that your factory ventilation system needs repair

An inefficient ventilation system not only makes the workspace stuffy but also greatly affects operational efficiency and the working environment.

However, not all businesses realize their factory ventilation system is failing until issues arise. Detecting abnormalities early helps save on future factory repair costs and time.

Common signs of a deteriorated factory ventilation system include:

- The factory air constantly smells musty, especially during the rainy season.

- Walls and ceilings show yellow stains, water seepage, or mold spots.

- Abnormally high temperatures inside the factory, especially near machinery areas.

- Fans operate weakly, inconsistently, or emit loud noises.

- Workers frequently feel suffocated, short of breath, or quickly fatigued while working.

Image 4. Signs your factory ventilation system is deteriorating

If you notice these signs appearing regularly, it's time to find suitable factory ventilation solutions as soon as possible. Delaying assessment and action may worsen the situation quickly, causing significant long-term damage.

5. How to deal with a deteriorating factory ventilation system

When your facility starts showing any of the above signs, it's time to review your entire factory ventilation setup. An underperforming system poses multiple health and production risks.

The best approach is to contact a reliable factory repair service provider to inspect the current structure and factory ventilation system.

They will conduct an on-site assessment, identify moisture-prone areas, measure airflow efficiency, and evaluate the overall ventilation capacity.

Image 5. Professional repair service offering optimal factory ventilation solutions

Based on the findings, the provider will suggest adjustments or upgrades, including dehumidifying measures, increasing fan power, adjusting airflow direction, and installing additional supply fans in stagnant zones.

This is also a good time to consider integrating temperature–humidity sensors for real-time monitoring and automatic airflow adjustments.

When factory ventilation is properly improved, it creates a clean, breathable, and stable working environment—enhancing both production quality and worker well-being.

6. Choosing the right ventilation equipment for your production model

Depending on the scale and type of production, businesses can choose different types of factory ventilation fans.

For small and medium factories, wall-mounted, roof-mounted, or ceiling exhaust fans can be used. In contrast, large-scale factories may require centrifugal ventilation systems or long-axis high-capacity fans.

Image 6. Choosing suitable equipment for your factory ventilation system

A common mistake businesses make is selecting equipment with unsuitable power, resulting in poor factory ventilation and high electricity consumption.

Additionally, inconsistent or poorly maintained equipment is another cause of unstable system operation.

Integrating factory ventilation with temperature-humidity sensors helps better manage airflow, automatically adjusting fan speed based on real conditions—saving electricity and extending equipment lifespan.

If you're unsure about which type of equipment to choose, consult specialists or trusted contractors for detailed advice.

7. Professional factory repair service from US Buildings

With years of experience in pre-engineered steel construction, US Buildings provides comprehensive factory repair and factory ventilation solutions—from on-site surveys and consulting to construction and long-term maintenance.

We understand that each factory has unique characteristics. That’s why our factory repair service packages are always tailored to specific production fields and the business’s real needs.

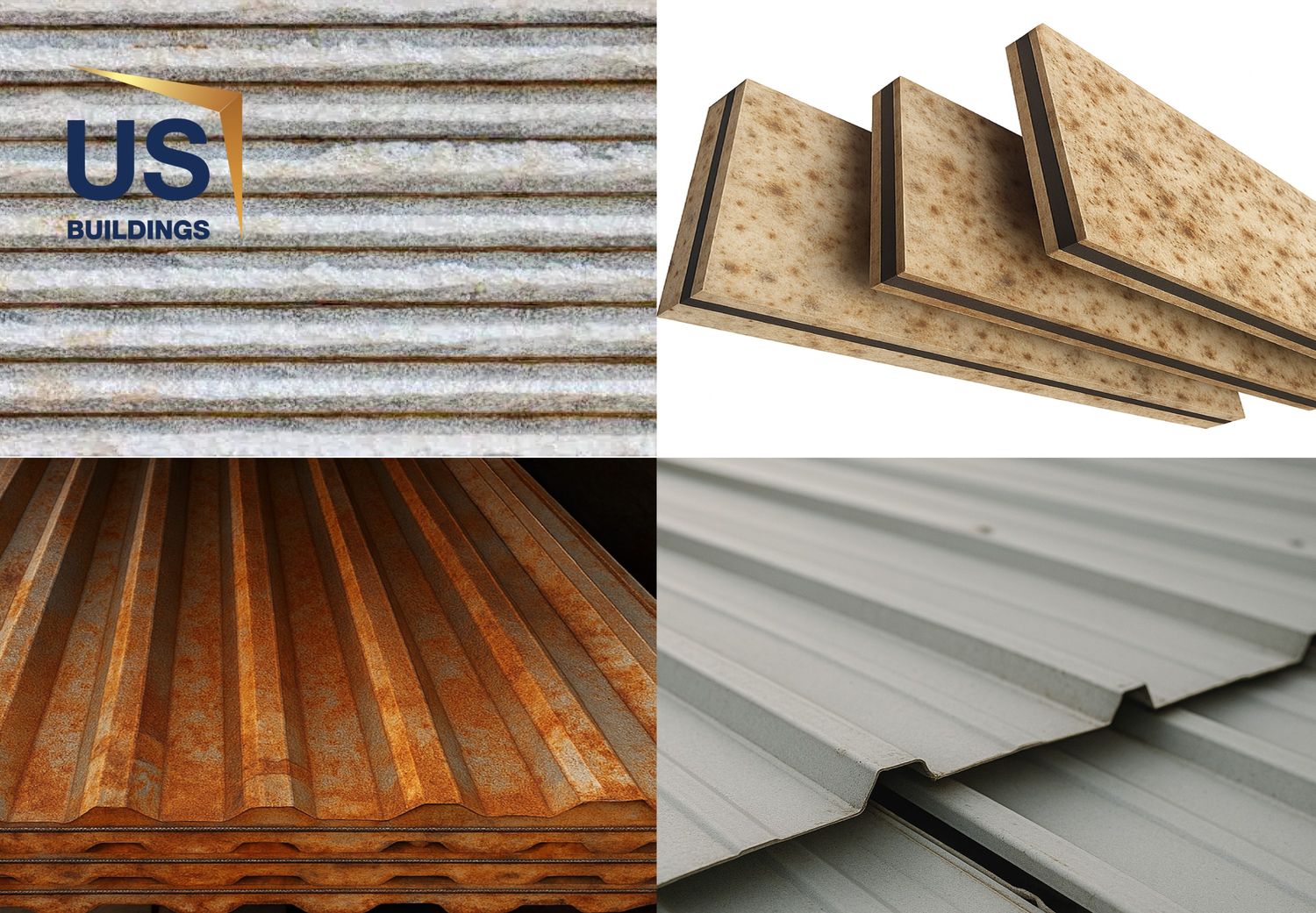

US Buildings offers specialized repair services, including:

- Replacing roofing sheets, skylights, insulation, trims, and gutters.

- Reinforcing corroded steel structures like columns, purlins, and trusses.

- Fixing water leaks in wall bases, roofs, and foundations.

- Applying epoxy coatings for floors, ceilings, and walls for aesthetics and dust resistance.

- Upgrading the factory ventilation system.

- End-to-end factory repair services from survey – quote – repair – warranty.

We use industry-standard materials and modern techniques to shorten construction time while ensuring durability, aesthetics, and maximum safety.

US Buildings is committed to supporting clients from free inspection to post-repair warranty.

Our expert engineers, practical experience, and dedicated service attitude ensure you receive budget-friendly solutions that optimize factory repair costs while delivering long-term performance.

You’ll also receive a 10% discount when booking a factory repair service with our company’s 365-day warranty policy.

US Buildings not only builds pre-engineered steel structures but also comprehensively renovates factories for sustainable and long-term production.

Image 7. US Buildings – Trusted, fast factory repair partner

Leave your contact HERE or call US Buildings at 0976 795 951 to receive FREE on-site consultation within 24 hours!