US Buildings - Complete and rapid factory repair service

Repair factory today with US Buildings - Professional factory repair services to optimize operations and prevent risks. Receive a free inspection!

1. Why is timely factory repair crucial when signs of damage appear?

Some might argue that delaying factory repair is acceptable when the damage isn't severe. However, this approach carries significant hidden risks and can lead to much higher costs in the long run. Performing timely and technically sound factory repairs is a crucial factor in ensuring smooth plant operations and the safety of all production activities.

- Ensuring workplace safety: Corroded steel structures or deteriorated roofing sheets can collapse at any moment, while outdated electrical systems pose fire hazards. Therefore, immediate factory repair helps create a safe working environment for employees.

- Maintaining production stability: Even minor incidents like a leaking roof damaging machinery can halt entire production lines, impacting efficiency and profits. Timely factory repair helps prevent such unexpected disruptions, ensuring machinery and production activities run continuously and without interruption.

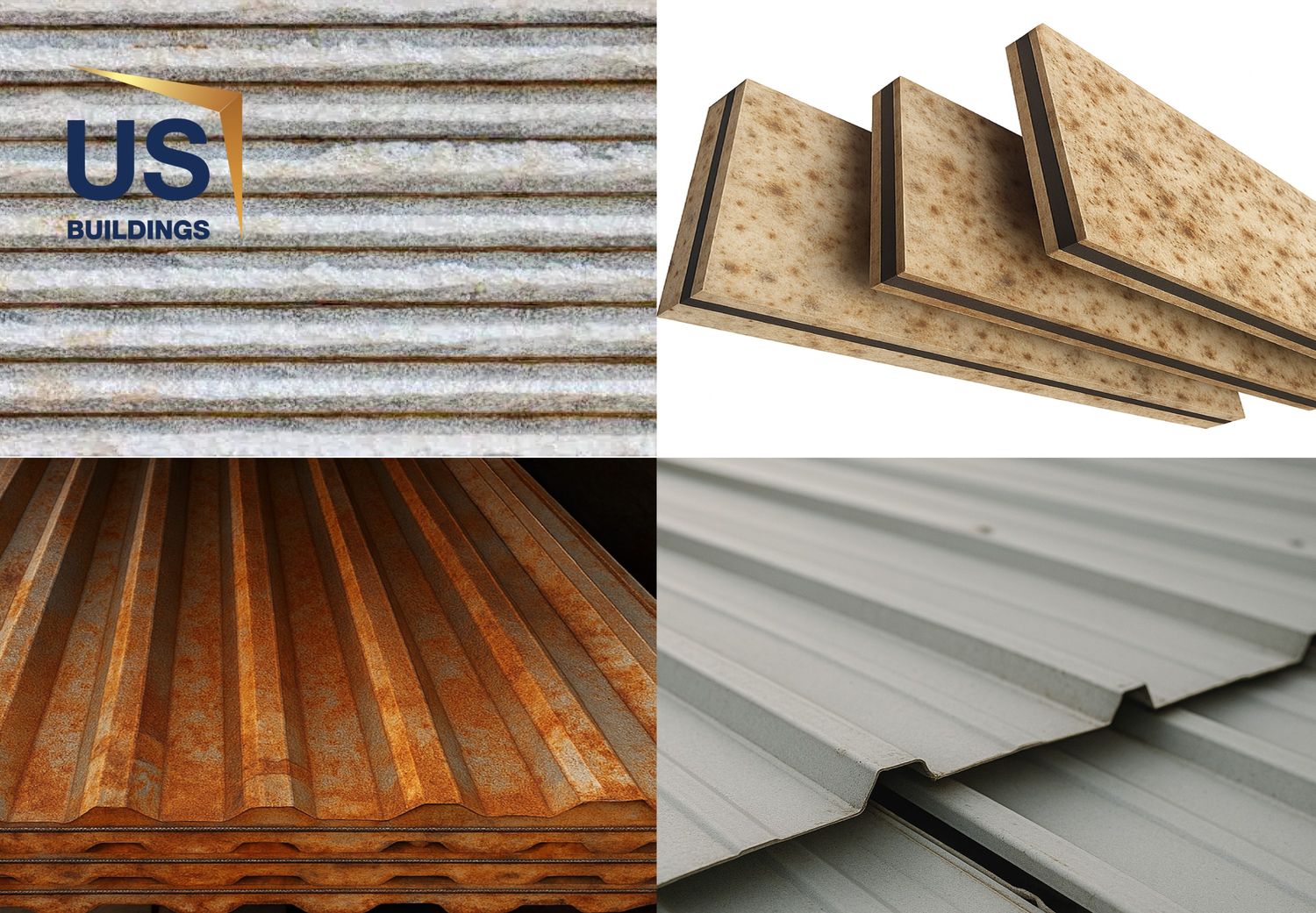

Image 1. Reasons for periodic and timely factory repair

- Achieving long-term cost savings: Addressing issues early prevents damage from spreading, avoiding major, unexpected, and substantial repair costs later. Proactively planning factory repair when initial signs of damage appear allows businesses to control budgets more effectively.

- Complying with legal regulations: Factories must meet state-mandated standards for structural safety and fire prevention and fighting. Timely factory repair ensures the facility remains compliant, avoiding legal complications and potential penalties.

- Increasing asset lifespan and value: A well-maintained factory has a longer operational lifespan and retains its aesthetic and functional value. Proper factory maintenance and upkeep are especially important if the business plans for future expansion or transfer.

2. Key areas to address during older factory repair

An older factory, operational for many years, often faces various deterioration issues. A comprehensive factory repair process requires thorough inspection across multiple areas to ensure no factor impacting operations is overlooked. Here are the core areas demanding attention:

- Steel structure: A thorough inspection for damage status – rust, corrosion levels, signs of deformation – is a critical first step. Welds and bolted connections also need careful examination. The factory repair plan may include reinforcement, anti-rust painting, or replacing components that no longer meet load-bearing requirements.

- Factory roof: As the roof directly endures weather impacts, regular checks for leaks, waterproofing integrity, decay, and rust on roofing materials are essential. When damage is found, immediate factory repair is necessary to prevent the situation from worsening.

- Drainage gutters: Especially in regions like the Southeast with extended rainy seasons, more frequent regular checks are needed. Businesses can seek reputable factory repair service for cleaning or replacement to ensure proper gutter drainage.

Image 2. Key areas for older factory maintenance

- Enclosing walls and Partitions: Inspect for cracks in walls, signs of moisture penetration, and peeling old paint. Carry out patching, waterproofing treatments, and repainting to ensure hygiene and aesthetics within the factory.

- Electrical system: Conduct a comprehensive review of all wiring, electrical cabinets, circuit breakers (CBs/MCBs), lighting systems, and grounding. Assess if the system still meets current operational power demands and the latest electrical safety standards, considering factory upgrade if necessary.

- Water supply and Drainage: Check the condition of pipes and valves, fix any leaks, and address blockages in rainwater and wastewater drainage systems.

- Fire prevention and Fighting (FPF) system: Perform periodic maintenance on FPF equipment (fire extinguishers, fire alarm systems, fire hydrants, etc.) according to official regulations.

- Other items: Depending on the factory's specific nature, additional checks may be needed for doors, rolling shutters, ventilation and cooling systems, wastewater treatment systems (if applicable), etc.

If you're unsure where to begin, contact a reputable factory repair service provider like US Buildings for consultation.

3. US Buildings - Your professional partner for factory repair and maintenance services

We offer a diverse range of services, from specific factory repair tasks and periodic maintenance to comprehensive renovation and replacement solutions aimed at upgrading and optimizing facility functionality.

What sets US Buildings apart:

- Free site inspection and Technical consultation: Our engineers will personally inspect the factory's current condition, analyze issues, and propose suitable technical solutions at no charge. This helps clients accurately estimate the factory repair costs involved.

- Flexible service capacity: We can handle maintenance and repair requests ranging from minor fixes to complex renovation projects, ensuring consistent quality for all clients.

Image 3. US Buildings offers professional factory maintenance services

- Guaranteed workmanship quality: We commit to using genuine, high-quality materials and employ a skilled construction team, ensuring the repaired facility achieves maximum durability and aesthetic appeal. Our 365-day Warranty Policy clearly demonstrates this commitment.

- Free and Transparent quotations: We guarantee no hidden costs during the factory repair process.

- 365-day service warranty policy: We apply a 365-day warranty to all completed work items, reflecting our commitment to material quality and execution techniques.

US Buildings is ready to serve your immediate factory repair needs in Binh Duong, Dong Nai, and surrounding key industrial zones.

4. Factory repair process at US Buildings

To ensure efficiency, transparency, and client satisfaction, we follow a professional and clear factory repair process:

Step 1: Schedule on-site inspection (Free)

Clients needing factory repair can contact US Buildings via phone: 0976 795 951. We will promptly receive your information, listen to your initial requirements, and provide preliminary service consultation.

After receiving your request, we will arrange a site visit at your convenience. Our experienced engineering team will come directly to your factory to conduct a thorough assessment of the current condition. This detailed inspection is completely free and aims to gather accurate data for the subsequent factory repair process.

Image 4. Schedule a free inspection with US Buildings

Step 2: Detailed quotation submission & Contract signing

Based on the on-site inspection results and client requirements, our technical team will perform an in-depth analysis, evaluate the scope of work, and propose the most optimal technical solutions and materials. US Buildings will prepare and send you a detailed, transparent quotation for each item, ensuring competitiveness and accuracy with no hidden costs.

Once the client reviews and agrees to the proposed technical plan and quotation, both parties will formally sign a service contract. The contract clearly outlines important terms regarding the scope of work, technical standards, execution schedule, total cost, payment terms, and responsibilities of each party.

Step 3: Execution, Inspection & Handover

Following contract signing, the construction team will commence the workshop repair work, endeavoring to complete it within 72 hours (this timeframe is subject to the project's scale and the scope of work).

The repair process is consistently and rigorously monitored for quality, occupational safety, and adherence to the schedule. Upon completion, we will conduct a detailed inspection and acceptance of each item, and handover will only proceed once the client expresses full satisfaction.

Step 4: Warranty & Technical support

Following the completion of the handover, clients can be assured by US Buildings' 365-day warranty policy. Should any items that underwent repair experience issues or malfunctions during operation subsequent to our maintenance services, our team will undertake the necessary rectification and repairs for you.

Even after the warranty period has expired, we remain readily available to offer support, provide consultation, and address any client inquiries, thereby ensuring the stable and efficient operation of the factory.

5. Contact US Buildings now for a free repair consultation

Don't let infrastructure issues affect your business operations. Proactively undertake factory repair work to ensure safety, efficiency, and sustainable growth.

Image 5. US Buildings - Reliable factory repair services

US Buildings is always ready to listen and provide optimal factory repair solutions for our clients in Binh Duong, Dong Nai, and neighboring areas. We are committed to delivering professional, high-quality services at reasonable costs with dedicated support.

Contact us now via phone: 0976 795 951 or leave your information HERE to receive technical consultation from our experts and schedule a completely FREE site inspection!