3 tips to extend your warehouse roof’s lifespan

Properly maintaining your warehouse roof helps prevent damage and extends its lifespan. Here are 3 simple tips to save long-term costs.

1. Why invest in warehouse steel roof maintenance?

Many businesses focus mainly on production equipment and overlook the fact that the warehouse roof serves as the first protective barrier for all valuable assets inside. A deteriorating roof can lead to disruptions in operations, damage to raw materials, and even halt entire production lines.

Image 1. Waterproofing treatments protects your factory

Maintaining, cleaning, and repairing your warehouse roof properly not only extends the lifespan of the entire facility but also significantly reduces long-term expenses. A durable roof that doesn’t leak or corrode helps maintain a safe and efficient work environment.

To achieve that, the first and most important step is to perform regular inspections and cleaning of the roof.

2. Tip 1: Perform routine inspections and clean your roof periodically

One of the primary reasons warehouse roof degrade quickly is the accumulation of dirt, debris, leaves, and rainwater over time. If not cleaned regularly, these elements trap moisture, which can cause rust, mold, corrosion, and damage the protective coating on the metal sheets.

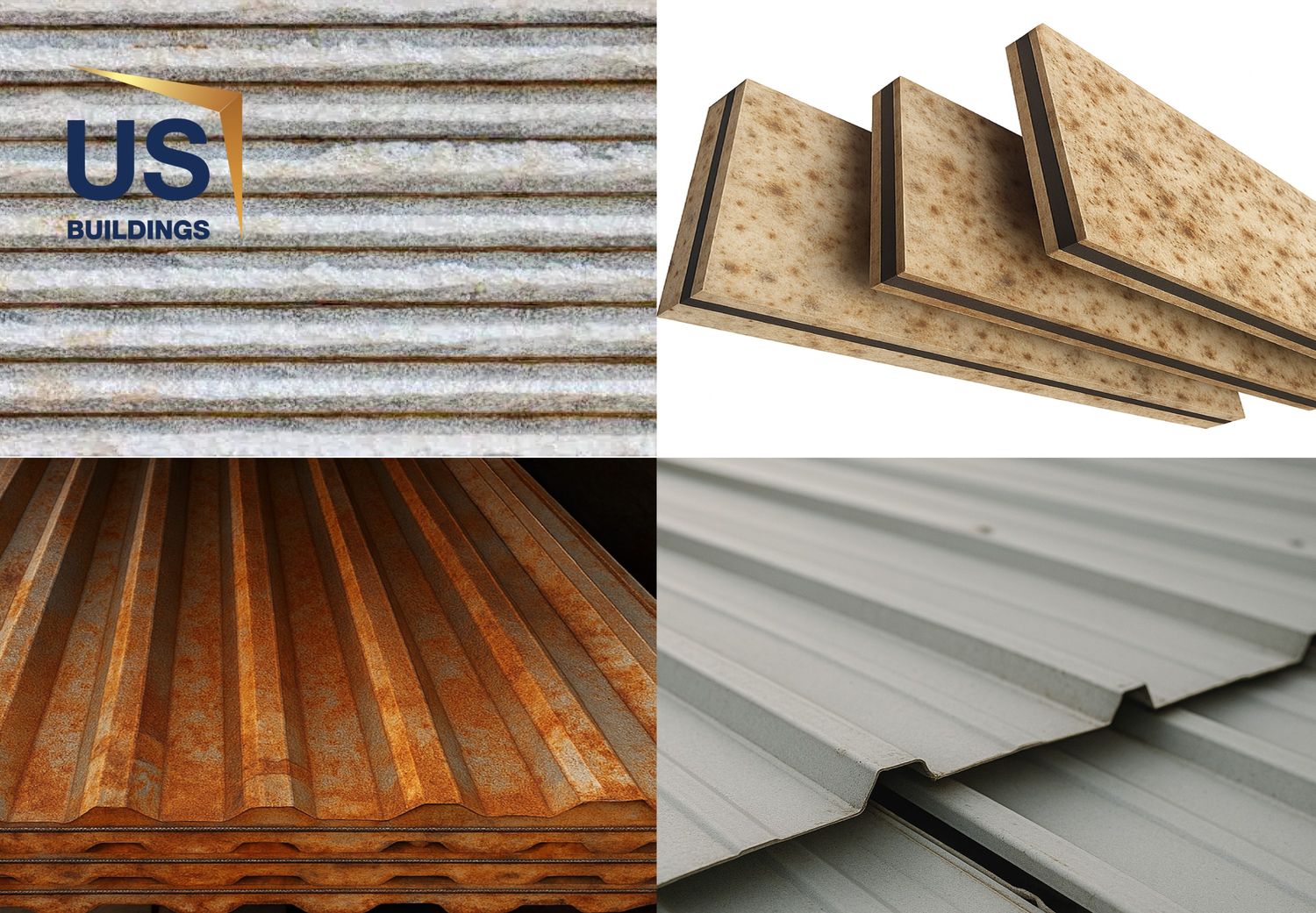

Image 2. Rusted steel after long periods without roof cleaning and maintenance

To prevent such damage and keep the roof in optimal condition, follow this recommended cleaning process:

- Clean the roof every 3 to 6 months.

- Use high-pressure water jets to remove dirt, algae, and debris.

- Avoid corrosive chemicals that may damage the protective coating.

- Inspect and clear water drainage systems, including gutters and downspouts.

Regular roof cleaning not only keeps the warehouse roof spotless but also allows early detection of potential problems such as punctures, cracks, or rust. Moreover, a clean and well-maintained roof creates a professional image for visitors, clients, and partners coming to inspect your facility.

3. Tip 2: Thoroughly fix punctures on metal roofs

Over time, punctures can appear on the warehouse roof due to impact, oxidation, or various environmental factors. If not dealt with promptly, rainwater can seep through, damaging the internal structure of your factory.

Image 3. Perforated roof caused by environmental factors

Common signs that your warehouse roof may be punctured include:

- Dripping water during rain: The most obvious sign is water dripping from the ceiling when it rains. This indicates a direct breach in the roof's integrity. Note the exact location of the drips to pinpoint the source of the leak.

- Widespread rust stains around the puncture: Even if you don't see immediate drips, the presence of widespread rust stains around a suspected puncture site is a strong indicator of water infiltration. These stains often appear on the underside of the roof panels or on the supporting structures.

- Unusual noises during wind or light impact: A loose or punctured section of the roof might produce unusual sounds, such as rattling, flapping, or creaking, during windy conditions or even from light impacts like hail. This suggests that the panel is not securely fastened or has been compromised.

How to repair perforated roof:

- Patch the holes using specialized waterproofing sealants or replace the section with new metal sheets.

- If there are multiple punctures, it is advisable to replace the entire panel to ensure safety.

- Regularly re-inspect repaired areas to prevent recurrence of leaks.

Early detection and timely repair of punctures can significantly prolong the warehouse roof’s lifespan and help avoid major repair costs. In addition, prompt treatment minimizes risks like short circuits or workplace accidents caused by water leakage, especially in manufacturing sectors that rely on electricity or sensitive equipment.

4. Tip 3: Install and maintain an effective rainwater drainage system

An often overlooked but critical factor in ensuring your warehouse roof lasts longer is a well-functioning rainwater drainage system. Improper drainage causes water to stagnate on the roof surface, increasing the likelihood of corrosion and water seepage.

The rainwater treatment system plays a vital role in protecting your warehouse roof from damage. A complete system includes gutters, downspouts, ground-level drainage paths, and collection pits with mesh filters to prevent blockages.

Image 4. The rainwater treatment system clogged with debris after prolonged use

A properly designed system allows rainwater to flow away quickly, avoiding local flooding. Efficient water drainage reduces stress on the foundation, prevents structural subsidence, and protects both the roof and the building’s frame from long-term damage.

Additionally, one essential maintenance tip is to conduct professional waterproofing treatments. This should be done periodically, especially before the rainy season or after severe storms. These are the times when vulnerable points like sheet joints, edge overlaps, and screw areas are most susceptible to leaks.

The waterproofing process includes thorough inspection of all joints and screw holes, sealing with specialized waterproof adhesives or sealing accessories, and installing ridge caps or flashing when needed.

An effectively waterproofed warehouse roof prevents leaks, maintains structural integrity, and ensures uninterrupted operations—particularly in industries where a dry environment is critical, such as food processing, pharmaceuticals, or electronics.

5. Proactively protect your warehouse roof with US Buildings

Taking care of your warehouse roof is the first step to safeguarding the safety, productivity, and cost-effectiveness of your entire factory operations.

By applying the three simple tips—routine cleaning, timely puncture repairs, and ensuring an effective rainwater drainage system—your business can confidently operate without worrying about leaks, damage, or sudden maintenance costs.

Image 5. US Buildings supports you through every stage of warehouse roof maintenance

It’s important to note that the cost of scheduled maintenance is far lower than the cost of replacing the entire warehouse roof when severe damage occurs. Being proactive with upkeep is a smart strategy for protecting your company’s bottom line.

Don’t wait for leaks to appear before acting—be proactive and protect your assets, your reputation, and your business continuity today.

If you don’t have an in-house maintenance team or require expert intervention, US Buildings is a trusted partner you can rely on. We offer comprehensive warehouse roof solutions—from inspection and repair to full replacement—following strict quality standards.

Here’s what we offer:

- Free survey – Quotation within 24 hours: We offer complimentary on-site surveys to assess the condition of your roof and provide a detailed, transparent quotation within 24 hours. Our goal is to provide you with clear information to make informed decisions without any obligation.

- Experienced construction team – Swift and efficient completion: Our highly experienced and skilled construction teams are dedicated to executing projects quickly and efficiently, minimizing disruption to your operations. We adhere to strict timelines and safety protocols to ensure a smooth and successful project delivery.

- Long-term warranty – Post-sale support: We stand behind the quality of our work with comprehensive long-term warranties. Our commitment extends beyond project completion with dedicated post-sale support, ensuring that your roof remains in optimal condition for years to come.

- High-quality materials – Standard compliant: We exclusively use high-quality, durable materials that meet stringent industry standards. This commitment to quality ensures the longevity and performance of your repaired or replaced roof, providing superior protection against the elements.

US Buildings is currently offering a 10% discount on roof repairs for the rainy season. This is the best time to perform maintenance before the weather worsens.

Contact us now via Hotline: 0976 795 951 to receive a free consultation and schedule an on-site survey. Or leave your information HERE for assistance.