Professional factory maintenance process with US Buildings

Your facility will deteriorate without a periodic maintenance plan. This article helps you understand the factory maintenance process to the highest standard.

1. Why is regular factory maintenance necessary?

Here are three key reasons why businesses should carry out a full and detailed factory maintenance process on a periodic basis:

- Ensure workplace safety: A neglected factory can harbor serious hazards such as rusty roofs, corroded steel frames, and cracked floors. Routine maintenance allows you to detect and address issues early, minimizing unexpected risks.

- Optimize operational efficiency: A well-maintained facility ensures smooth production flows, avoiding costly interruptions from sudden breakdowns. This directly boosts productivity and profitability.

- Extend the building’s lifespan: A service that fully follows a professional factory maintenance process not only focuses on repairs but also anticipates potential risks. This proactive approach helps extend the lifespan of the facility by many years beyond its original expectations.

Image 1. Factory maintenance process completed and handed over – neat and clean

2. Warning signs that your factory needs urgent maintenance

An effective factory maintenance process always begins with the accurate and timely detection of damage. Check if your factory is currently facing any of the following issues:

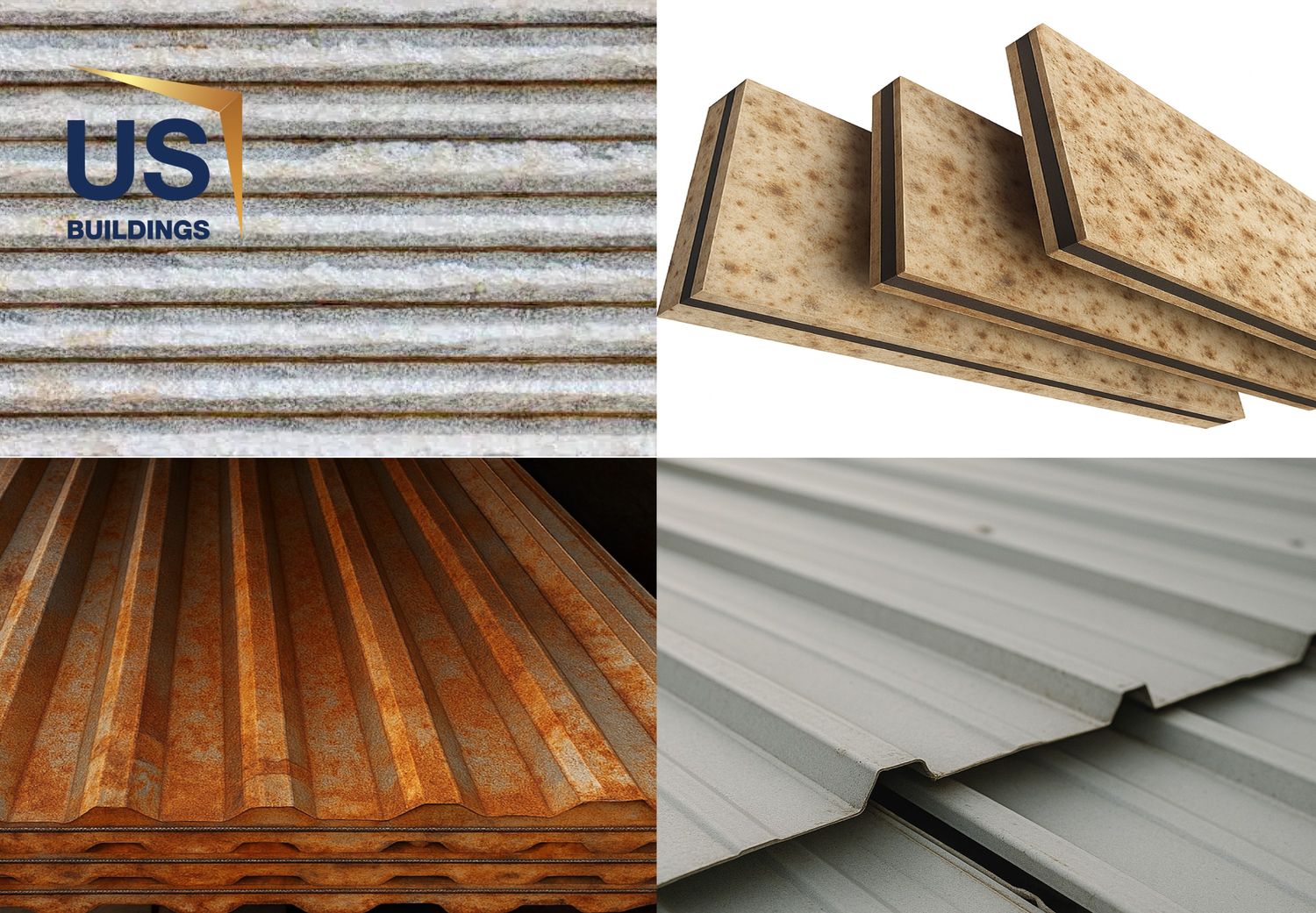

- Rusted, perforated, or leaking roofing panels.

- Sagging or cracked steel trusses.

- Cracks, peeling paint, or mold on walls.

- Poor drainage leading to pooling water.

- Out-of-date or non-compliant fire-protection systems.

If your factory shows any of the above signs, don’t hesitate — contact a reputable company like US Buildings for consultation on a comprehensive and effective factory maintenance process.

Image 2. Scheduled inspection and factory renovation planning

3. Why choose a reputable provider for factory maintenance?

To ensure the factory maintenance process is carried out efficiently, promptly, and with technical accuracy, it's best to work with reputable service providers. They offer numerous advantages that businesses can fully trust:

- Hands-on experience with various projects: With hundreds of projects completed across the country, a professional provider understands every detail of the factory maintenance process and the specific environmental conditions involved.

- Skilled engineers and technicians: Reputable companies have specialized teams experienced in repairing steel structures and metal roofing, ensuring the work is carried out to standard following a professional factory maintenance process.

Image 3. Factory repair should be done before the rainy season

- Diverse, flexible services: From factory roofing replacement and heat-resistant painting to expanded drainage systems and production-area extensions, solutions adapt to your real needs.

4. Factory maintenance process with US Buildings

US Buildings not only delivers pre-engineered steel construction but also provides full-scope maintenance services via a transparent, six-step factory maintenance process:

Step 1: Receive request & on-site survey

We gather your requirements, schedule a free on-site survey, and assess key components like roofing, steel frames, trusses, flooring, walls, and fire systems.

Step 2: Assess condition & recommend solutions

After the inspection, the contractor will analyze the causes of factory deterioration such as mold, rust, leaks, or metal corrosion. Based on this assessment, they will propose appropriate solutions and a standard factory maintenance process tailored to the actual condition and the client’s budget.

Image 4. Regular inspection and factory roofing replacement

Step 3: Quotation & detailed maintenance plan

We provide a clear quotation for each task, with a comprehensive project plan covering timelines, manpower, materials, and safety procedures. Transparent contracts ensure timely and quality delivery.

Step 4: Execution according to standards

Our team implements the plan following a professional factory maintenance process, ensuring no production interruptions. We use high-quality materials and strictly adhere to safety and cleanliness protocols.

Step 5: Completion inspection & handover

The completed work meets all technical standards, with no hidden costs, and includes a clear warranty policy.

Step 6: Post-maintenance support

We guide clients on self-checks and maintenance practices post-project. The work is covered by a 365 - day warranty, and we offer prompt support for any unexpected issues.

5. US Buildings – Your trusted partner in factory maintenance

A professional factory maintenance process helps maintain stable production and protects your business reputation. US Buildings is committed to providing safe, efficient, and cost-effective solutions with a team of highly experienced technicians.

Don’t let minor damage turn into major problems. Let US Buildings be your partner in enhancing your facility's quality - from factory repair to full - scale factory renovation.

Image 5. US Buildings delivers top-tier maintenance services for businesses

If you're looking for a reliable – fast – efficient partner this rainy season, don’t hesitate to contact us for a free consultation and custom solutions, including roof leak repairs and optimal factory renovation.

US Buildings offers full warranties on both materials and workmanship, with on-site support within 24 hours for any arising issues. Currently, we’re offering a 10% discount along with a warranty of up to 365 days.

Contact us now at 0976 795 951 or leave your information HERE to schedule your free technical inspection with our expert team!