Causes and solutions for factory steel column base corrosion

A corroded steel column base poses a serious risk to a factory. This article will analyze the causes, consequences, and comprehensive technical solutions for this issue.

1. Analysis of the main causes of steel column base corrosion

The steel column base plate is the main load-bearing component of the structure, but it is also the location most vulnerable to corrosion. A lack of understanding of the causes will lead to mistaken, costly, and ineffective preventive measures.

Therefore, the first step to protecting the structure is to accurately identify the risks that cause this condition. Below are the main factors causing steel column base corrosion to be aware of:

- Moisture and water: This is the number one factor. Rainwater splashing in, damp factory floors, moisture seeping up from the ground, or pipe leaks will create an ideal environment for oxidation (rusting) to develop.

Image 1. A severely rusted steel column base plate

- Corrosive chemicals: In specialized manufacturing factories (chemicals, textiles and dyeing, food processing, plating), frequent contact with acids, salts, alkalis, and other corrosive compounds will accelerate the destruction of the steel column base structure.

- Environmental factors: Factories located near the sea are affected by salt vapor in the air. Industrial zones with high concentrations of SO2 and NO2 emissions are also a cause of severe corrosion.

- Errors during construction: The use of low-quality steel materials, a protective paint layer that is too thin, or a poorly constructed drainage system will make the steel column base vulnerable from the very beginning.

2. Signs of a corroding factory steel column base

Regular inspection of the steel column base area plays a key role in the early detection of corrosion signs. This identification can be done through visual observation, focusing on the following abnormal manifestations:

- Appearance of yellow, reddish-brown rust spots on the surface of the steel column base.

- The protective paint layer is blistering, cracking, or peeling off in patches.

Image 2. The steel column base shows yellow and reddish-brown rust spots on its surface

- The surface of the steel column base is pitted, with tiny pin holes appearing.

- When tapping on the column, the sound is no longer solid and firm.

- More seriously, the steel column base is visibly thinned, deformed, or bulging in the area of contact with the concrete foundation.

If you notice any of the above signs, it's time to call a professional factory maintenance service to inspect and assess the steel column base.

3. Serious consequences of corrosion if left untreated

Deterioration due to corrosion at the steel column base is a process with many potential risks. Failure to address it in a timely manner will increase the risk of structural failure, leading to the following serious consequences:

- Reduced load-bearing capacity: The corroded steel core will reduce the load-bearing cross-section of the column. Over time, the steel column base will no longer be strong enough to support the load of the roof, beams, and internal activities, leading to a weakened structure.

- Risk of factory collapse: This is the most catastrophic consequence. When one or more main columns are weakened to their limit, they can suddenly collapse, endangering the lives of workers and completely destroying assets and machinery.

Image 3. A weakened steel column base poses a risk of factory collapse

- Huge repair costs: The cost to reinforce the steel structure or replace a collapsed part of the factory is many times higher than the cost of maintaining and repairing a corroded steel column base from the beginning.

- Production disruption: Major repairs or incident recovery will force the factory to cease operations, causing heavy economic losses.

4. Effective anti-corrosion and repair methods for steel column bases

Depending on the level of corrosion of the steel column base, professional units will apply appropriate methods. Basically, the process will include surface treatment steps and the application of protective solutions:

- Surface cleaning: Completely remove rust and old paint using mechanical methods such as grinding machines, wire brushes, or most effectively, sandblasting or shot blasting.

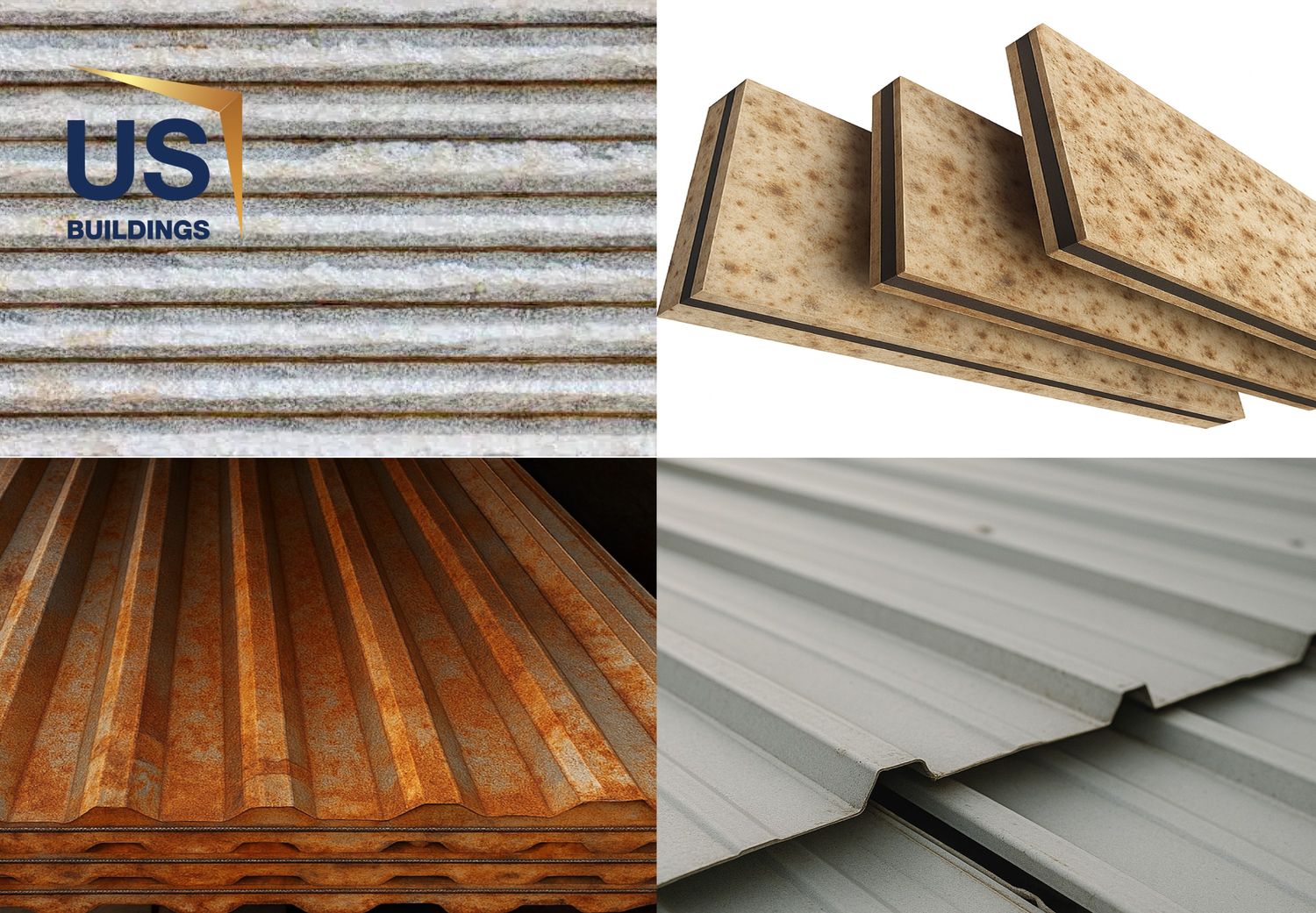

Image 4. Effective anti-corrosion and repair methods for a steel column base

- Specialized coating application: After cleaning, the steel surface will be coated with an epoxy-based anti-rust primer, followed by two layers of epoxy color topcoat to create a perfect barrier, isolating the steel from the external environment.

- Reinforcement with steel plates: In cases where the steel has been excessively thinned by corrosion, new steel plates must be welded on to compensate for the lost cross-section, ensuring the load-bearing capacity of the steel column base.

5. US Buildings' professional process for treating and repairing steel column base corrosion

To ensure absolute efficiency and safety, the factory maintenance process must be followed precisely and strictly. At US Buildings, we perform the following steps:

Step 1 - Survey & Assessment: A US Buildings engineer will come to the site to survey, measure, and assess the extent of the steel column base corrosion and the actual load-bearing condition of the structure.

Step 2 - Solution planning & Quotation: Based on the survey results, we will advise on the most optimal solution (painting, concrete encasement, reinforcement, etc.) and send a detailed, transparent quotation.

Image 5. The factory maintenance process at US Buildings is followed precisely and strictly

Step 3 - Surface treatment execution: Implement safety measures and proceed to thoroughly clean the surface of the steel column base with specialized equipment.

Step 4 - Repair & Reinforcement: Apply the agreed-upon technical methods to repair, restore, and reinforce the steel column base.

Step 5 - Final coating application: Apply an epoxy anti-rust, anti-corrosion paint system for long-term structural protection.

Step 6 - Acceptance & Warranty: Hand over the project to the client, accompanied by a long-term warranty commitment for the quality of the workmanship.

6. US Buildings: Comprehensive solutions to protect your factory from corrosion risks

US Buildings understands that the safety and stability of the structure are the top priorities for any business. The issue of steel column base corrosion is not just a common damage but a potential risk that directly threatens production activities and personnel safety.

With in-depth experience in the field of industrial factory maintenance and repair, we are committed to providing effective and reliable solutions for steel column base corrosion, based on core principles:

- High technical expertise: The engineering team at US Buildings will directly survey and accurately assess the level of corrosion, proposing the most suitable treatment plan for the current state of the structure, ensuring technical efficiency and absolute safety.

Image 6. US Buildings - A reputable factory maintenance service

- Optimal and transparent solutions: We advise on solutions that best fit the business's budget, from protective coatings to structural reinforcement. The entire process and costs are presented clearly and in detail, with no hidden fees.

- Top-Quality workmanship: We commit to using genuine, high-quality specialized materials (steel, anti-rust epoxy paint) and a skilled construction team, ensuring that the repaired steel column base has superior corrosion resistance and long-term durability.

- Reliable warranty policy: Businesses can operate with complete peace of mind with our long-term warranty policy for all repair and reinforcement items. We are always ready to provide prompt technical support when needed.

Don't let steel column base corrosion become a latent threat to your factory. Take action today!

US Buildings is offering a FREE on-site SURVEY & ASSESSMENT program for all customers. Our team of engineers will help you accurately determine the extent of the damage and propose the most effective treatment plan.

For interested customers, please contact US Buildings immediately via hotline 0976 795 951 or leave your contact information HERE. We are honored to serve and support the safety and sustainable development of your business.