Understanding rust in factories: Levels, causes, and impacts

Rust weakens your building over time. Schedule a free inspection today to get a FREE quotation!

1. What causes steel structures to rust in factories?

Steel is a popular choice for structural frames in modern industrial buildings because of its strength and durability.

However, factory environments often have high humidity, dust, chemicals and poor ventilation. These factors make steel components more likely to corrode overtime, leading to rust.

When rust starts to form, it creates small spots of damage on the steel surface. Over time, these spots can break down the protective paint layer, allowing water and oxygen to reach deeper into the metal.

This causes the steel to corrode from the inside out, lose its strength, and even become deformed. That is why regular maintenance is so important. If the problem is not detected early, the entire factory structure can become unstable, and in serious cases, it could even collapse.

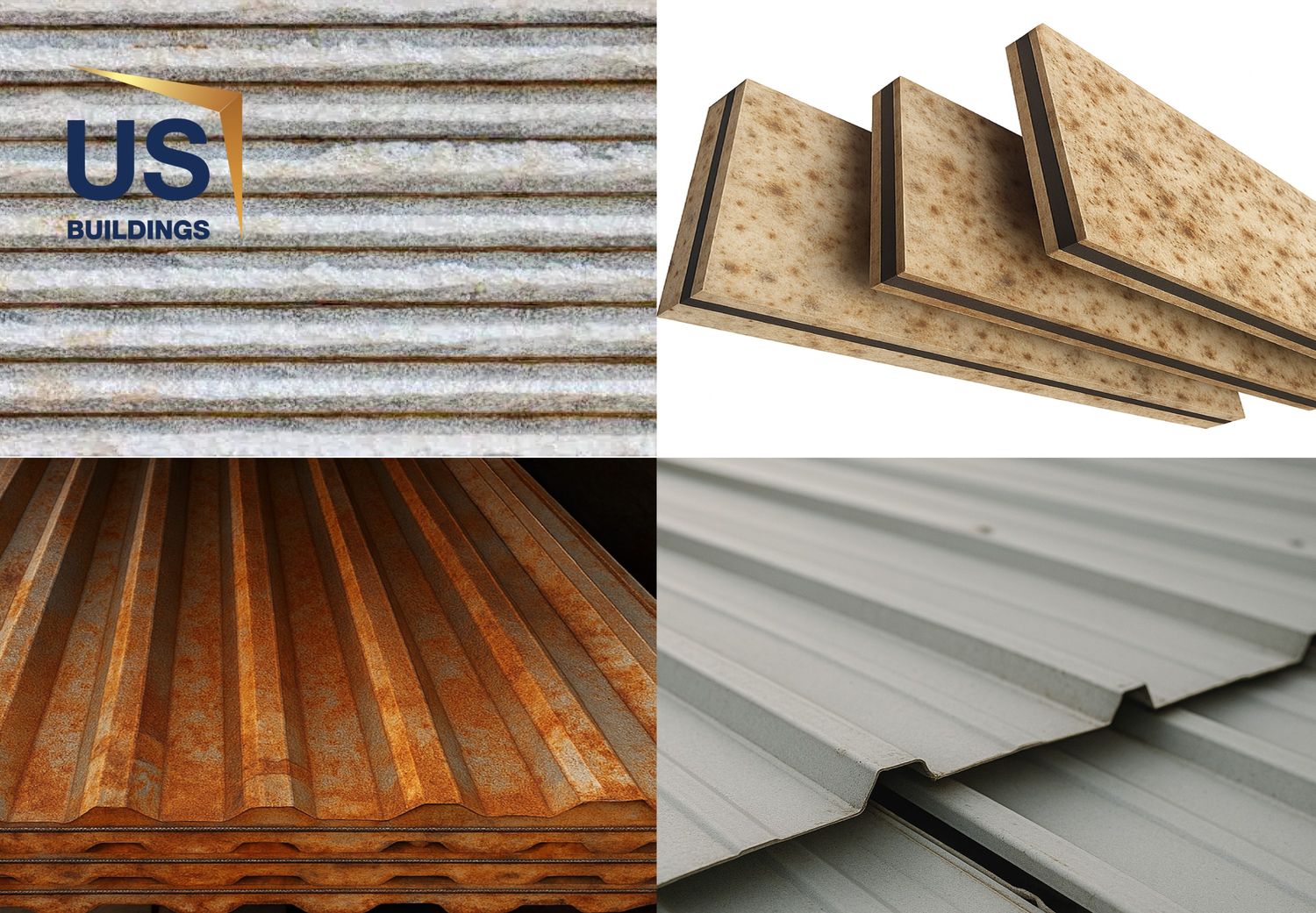

Image 1. Common causes of rust on steel structures in factories

2. Some key areas to inspect and treat for rust

Not all steel structures are equally affected by rust. Due to physical properties and environmental conditions, certain areas are more prone to corrosion. Therefore, understanding vulnerable locations helps make inspection more efficient, saving both time and cost.

Here are the most common areas where rust often develops and should be prioritized:

- Welds and steel connections: Welded joints and bolt connections are often overlooked during anti-rust coating. If the protective paint does not fully cover these areas, moisture and air can seep in over time, causing rust to form.

- Roof and gutters: Factory roofs and gutters are exposed to constant sunlight, rain, dust, and industrial waste. If not cleaned regularly, remaining water and debris can accelerate rust, especially where the paint has peeled or cracked.

- Steel columns and load-bearing beams: These are key structural components and can absorb moisture from leaking roofs or walls. If the protective layer is damaged, rust can weaken the steel from the inside. Therefore, regular inspections here are crucial for workplace safety.

Image 2. Areas need inspection to keep the factory structure safe

3. How different levels of rust affect steel structures

Rust does not happen immediately, it develops gradually through multiple stages, from mild to severe. Each level has different impacts on the structure’s strength and safety.

Understanding these levels helps businesses assess the condition of their factory and decide when and how to have factory repairs before damage gets worse.

Level A: Early warning signs

At this stage, rust is just starting to form on the steel surface. It usually appears as tiny brown spots. The steel is still mostly protected by its metal cladding, and the rust is minimal.

Level B: Surface damage begins

At this level, rust has started to eat into the steel surface. You might see small holes, peeling paint, or even rough patches where the steel is exposed.

Image 3. Treating rust early helps to reduce the costs of factory repairs

Level C: Structural weakening begins

At this stage, the protective cladding has completely peeled off, leaving the steel structure fully exposed. The steel quickly loses its cross - sectional area, which significantly reduces its load-bearing capacity and overall structural strength.

If rust at this level is not identified and treated promptly, the steel may lose part of its structural function, posing serious safety risks. This not only shortens the building’s lifespan but also increases the chance of collapse if no action is taken in time.

Level D: Critical structural damage

This is the most severe level of rust. The steel has suffered major corrosion. Visible signs such as holes, cracks and heavy surface damage are easy to see by eyes. The steel has lost both its protective coating and structural integrity.

At this point, the only practical solution is to completely replace the damaged components or undertake a full-scale factory renovation. This is both time-consuming and expensive, which is why regular steel structure maintenance is essential to avoid this stage.

Image 4. Regular steel structure maintenance helps prevent serve rust

4. Professional rust inspection procedure at US Buildings

We offer a comprehensive rust inspection service to help our clients maintain stable operational performance and extend the lifespan of facilities.

With a professional and transparent factory maintenance procedure, US Buildings will optimize solutions for each type of structure, helping to prevent risks that could affect the integrity of steel frameworks.

Step 1: Schedule an inspection

Clients who need a facility inspection can simply contact US Buildings via 0976 795 951. Our technical team will provide free consultation and schedule an on-site assessment. The inspection is conducted directly at the facility to identify any potential signs of rust.

Step 2: Quotation and contrast signing

Based on the inspection results and client needs, US Buildings will provide a clear and detailed quotation for each service item. Every recommendation is carefully calculated to optimize costs and ensure no unexpected charges outside the agreed contract.

Image 5. Professional factory repairs team at US Buildings

Once the clients agree with the proposed rust recommendation plan, both parties will proceed to sign an official contract. The contract will clearly outline all terms and conditions for both sides.

Step 3: Repair, inspection and handover

After the contract is signed, the repair process is carried out under the supervision of our experienced engineering team. Each step is executed according to strict standards to ensure effectiveness and thoroughly resolve rust issues at key structural points.

Step 4: Technical support and long-term warranty

US Buildings offers a warranty up to 365 days for all completed work following rust treatment. During and after the warranty period, we continue to provide technical support as needed to address any issues, ensuring your facility operates at peak performance.

Image 6. US Buildings - A trusted provider transparent factory maintenance procedure

5. Contact US Buildings for a free rust inspection

Don’t let the hidden rust silently affect your factory’s operations. Minor damage, if left undetected, can lead to costly repairs or even production downtime. Take the initiative to maintain your facility today!

If you need a rust inspection, contact US Buildings directly through 0976 795 951 or leave your information HERE to schedule a FREE inspection!