7 signs your steel structure factory needs inspection now!

A steel structure factory must be regularly inspected and repaired to prevent deterioration that could pose risks to safety and disrupt production.

1. Deflection or slight deformation of beams and columns

Beams and steel columns for factories are the primary load-bearing components of a steel structure factory.

When there are signs of deflection, bending, or slight deformation. Even if the overall structure is not yet compromised, this is an early warning that the structure is beginning to degrade.

Image 1. Deformed steel column for factory

Causes may include overloaded conditions, changes in functionality, or material aging. Early inspection and repair will help prevent severe deflection that could lead to collapse.

2. Loose or rusted welds and bolts

The welds and bolts in the steel structure factory are critical to maintaining its structural integrity. If welds show cracking, peeling, or if bolts are loose or rusted, these are clear signs of weakening.

Image 2. Loose, rusted welds and bolts affecting steel factory structure

Minor issues can be fixed by reinforcing or replacing bolts. For more severe cases, comprehensive factory repair will be required to ensure safety.

3. Appearance of small cracks on the structural surface

Small cracks or micro-cracks on the surface of beams, steel columns for factory, or cladding sheets are also signs that the steel structure factory is experiencing excessive mechanical or thermal stress.

Image 3. Cracks appearing on factory steel structure surface

Cracks can result from thermal expansion, dynamic loads, or construction errors. Routine inspections help detect and resolve these issues early.

4. Strange noises when under load or in strong winds

An often-overlooked but important sign is the presence of strange noises coming from the steel structure factory when subjected to strong winds or heavy loads.

Image 4. Squeaking noises from factory steel structure

Sounds like "cracking" or "creaking" may indicate weakened joints, thermal expansion, or structural displacement. These signals require immediate investigation to prevent potential hazards.

5. Unusual vibrations during operation

If abnormal vibrations are felt in the steel structure factory during plant operations, this may indicate a reduction in overall stiffness and alignment.

Image 5. Vibrating factory steel frame structure

Such vibrations often result from foundation weakening, loose connections, or a compromised factory steel frame. Inspection, reinforcement, or replacement is necessary.

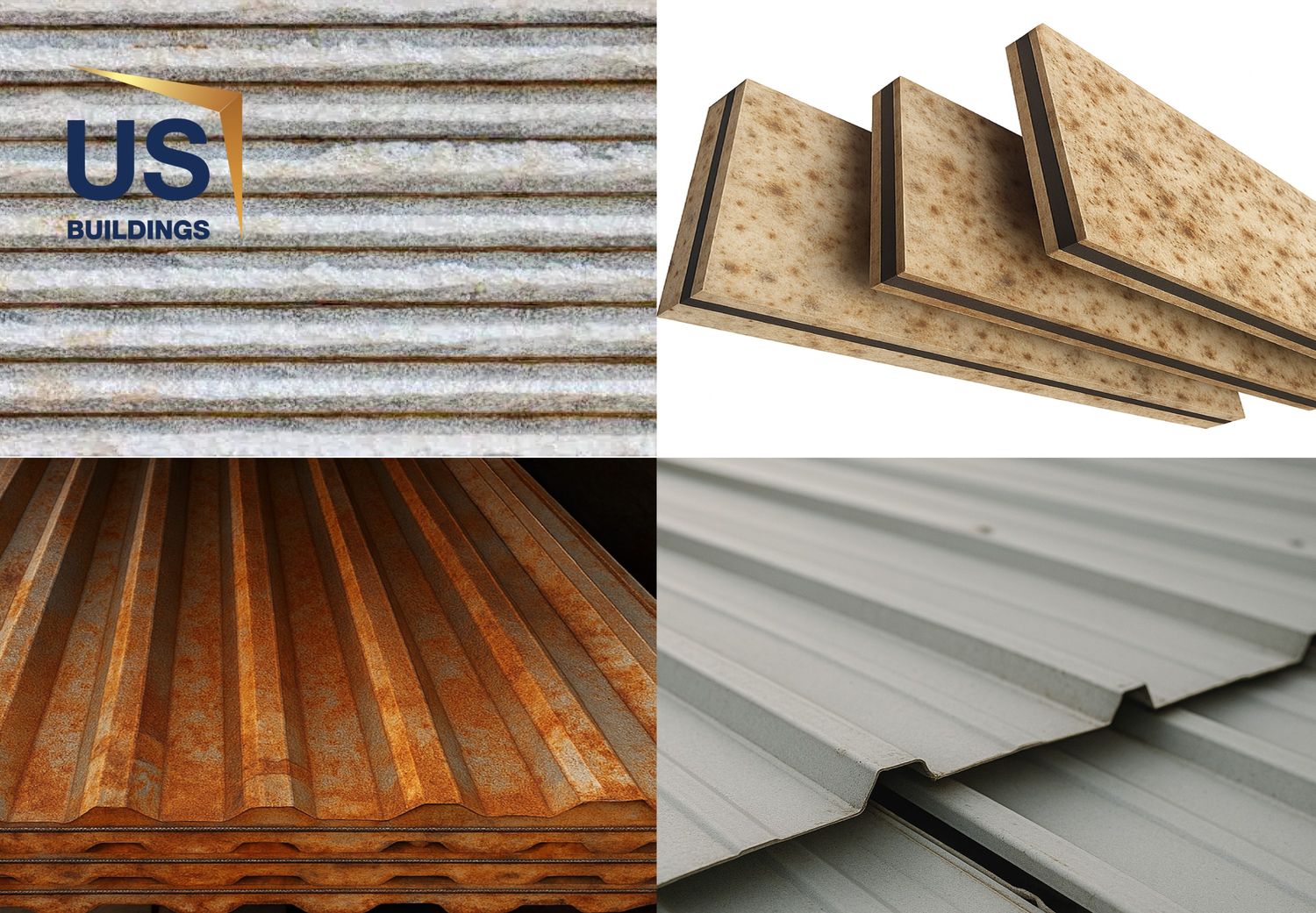

6. Corrosion on steel surfaces due to chemicals or rain

Steel structure factory buildings used in chemical industries, food processing, or exposed outdoor environments are particularly susceptible to corrosion.

Image 6. Corroded steel surfaces caused by chemical exposure

When steel surfaces show peeling protective coatings and rust patches, corrosion is already underway. Anti-corrosion treatment, repainting, or component replacement is required.

7. Structural impact from forklifts or cargo

Constant movement of forklifts, machinery, or collisions with pallets can also damage the steel structure factory.

Image 7. Impact from forklifts or machinery on factory floor

Minor impacts can cause deformations or dents in steel columns for factory or bracing members over time. Without prompt factory repair, these weak points may lead to major structural issues later.

8. Why should you inspect the steel structure factory regularly?

The steel structure factory is the core load-bearing system that enables long-term, stable operations. Without regular inspection and maintenance, hidden risks can result in:

- Increased risk of collapse.

- Production disruptions.

- Property and human losses.

- Higher factory repair costs later.

Image 8. Routine inspection helps avoid costly factory repairs later

Therefore, manufacturers should implement scheduled inspections and maintenance. Depending on production type and environment, inspection cycles should range from every 6 months to once a year.

9. How to inspect and handle weak steel structure factory issues

When any of the 7 signs appear, the first step is to conduct a full inspection of the steel structure factory by professional service providers.

Image 9. Contact professional repair services when weak structure signs appear

A reputable factory repair service will typically follow these steps:

- Detailed on-site survey.

- Assessment of structural damage.

- Proposal of appropriate factory repair solutions.

- Post-repair safety verification.

If the issues are found in main load-bearing elements like steel column for factory or factory floor, priority handling is critical to ensure absolute safety.

10. US Buildings – Professional steel structure factory inspection and factory repair services

With years of experience in pre-engineered steel building construction and factory repair, US Buildings is a trusted partner for businesses seeking inspection or repair of their steel structure factory.

We provide comprehensive solutions from site assessment, structural evaluation, to reinforcement and routine maintenance. Every project is carefully inspected to ensure absolute safety for people and property, optimizing cost.

We understand that each steel structure factory has different technical specifications and operational environments, our team will recommend the most suitable solutions for each specific need.

US Buildings provides services including:

- Inspection of load capacity and durability of the entire steel structure factory.

- Reinforcement or replacement of steel columns for factory, beams, purlins, and compromised frame components.

- Repair of welds, loose or rusted bolts to ensure safe load-bearing capacity.

- Reinforcement or replacement of weak points in factory steel frame due to mechanical or aging factors.

- Correction of sagging, abnormal vibrations in factory floor and secondary structures

- Anti-rust treatment, epoxy coating to extend service life of steel components.

- Comprehensive upgrades or renovations of aging steel structure factory frames according to new operational requirements.

Our commitment to clients:

- Fast, professional inspection–consulting–repair process without production interruptions

- Use of high-standard materials and techniques to ensure long-term safety and durability.

- Skilled and experienced engineers and workers able to handle complex situations.

- Clear warranty and maintenance policies to ensure lasting performance.

- Transparent pricing with detailed quotes, optimized budget for each factory repair scope.

Image 10. US Buildings – Trusted factory repair provider in Vietnam

Our professional steel structure factory inspection and factory repair services will help you operate with confidence, safeguarding your entire production system.

Leave your contact details HERE or contact US Buildings via hotline 0976 795 951 for FREE inspection booking within 24 hours!