Industrial metal roof leak prevention: A comprehensive rainy season solution

The prolonged rainy season causes leaks, flooding, and corrosion of structural components, accelerating facility deterioration. Industrial metal roof leak prevention is an effective solution to protect production operations.

1. The condition of southern Vietnam’s factories at the start of the rainy season

Southern Vietnam's rainy and prolonged climate causes factories - especially those with metal roofs and steel structures - to deteriorate rapidly without timely maintenance. Therefore, industrial metal roof leak prevention becomes essential to ensure stable operations every rainy season.

- Leaky metal roofs in factories: If not repaired early, they can worsen, affecting both structural integrity and production activities. Early-stage industrial metal roof leak prevention helps avoid costly future repairs.

- Factory flooding: Drainage systems that are not regularly maintained can easily become clogged with leaves and debris. This prevents rainwater from draining properly, leading to flooding, damaging the factory floor, and even causing long-term foundation subsidence if timely factory renovation is not carried out.

Image 1. Installation of sealing patches to reduce factory flooding

- Steel structure corrosion: Prolonged high humidity creates ideal conditions for metal oxidation, causing rafters, purlins, and gutters to rust quickly. This reduces the structure’s lifespan and compromises its safety, especially if anti-rust coating is not applied regularly.

- Electrical and lighting system failures: Water seeping into inadequately insulated electrical systems can cause leakage, disrupt production, and pose safety risks to workers.

2. Common causes of factory damage during the rainy season

There are frequent issues during the rainy season such as leaks, structural deterioration, and factory flooding. To prevent unwanted situations, businesses should pay attention to the following common causes:

- The initial design did not adequately account for wind and rain loads.

- Construction did not meet technical standards, especially at joints and roof drainage systems.

Image 2. Preventing factory leaks by sealing metal roof screw heads

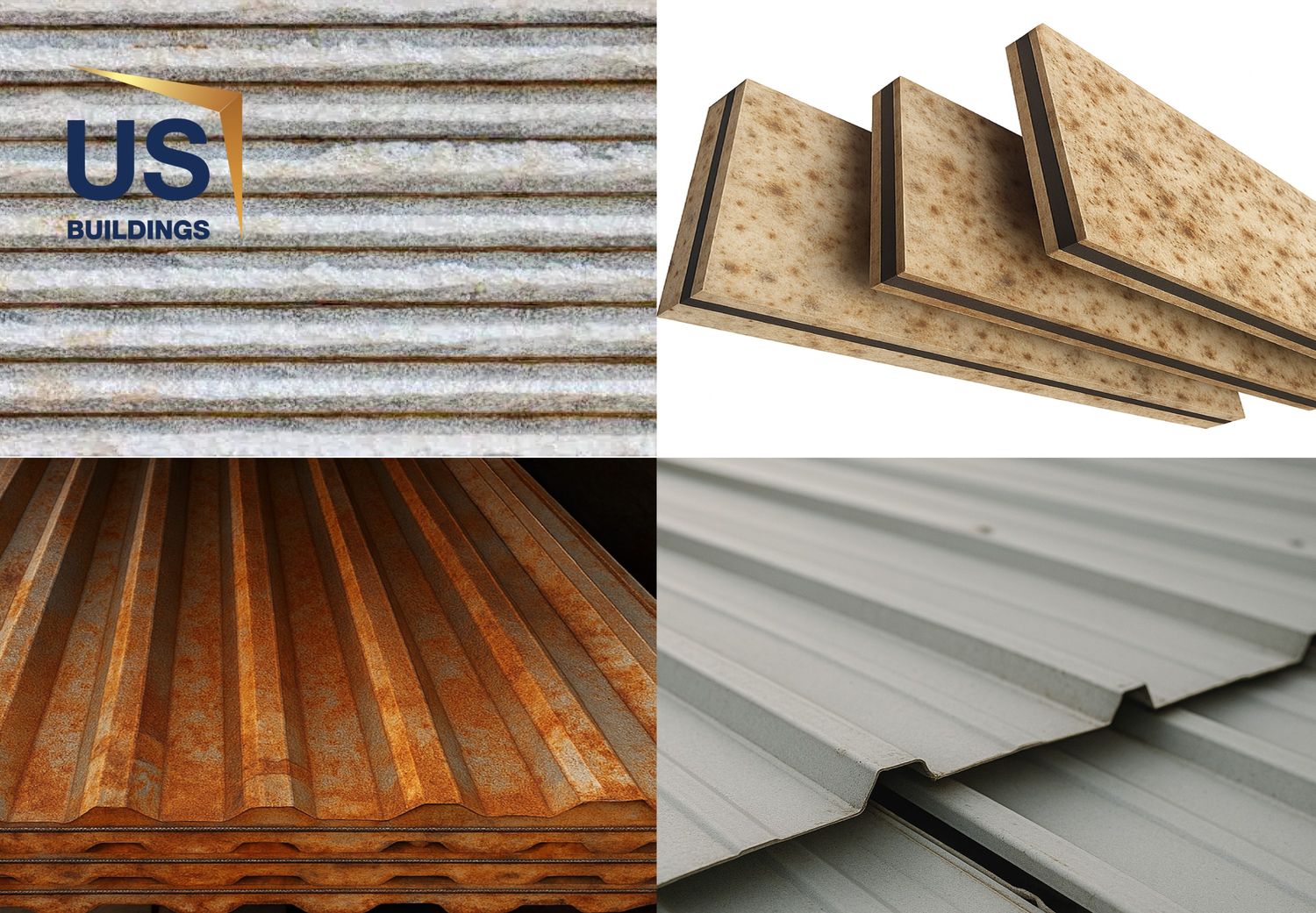

- Using low-quality materials that deteriorate easily over time.

- Lack of regular maintenance, leading to delayed detection and repair of minor damages.

- The impact of climate change has led to heavier and more prolonged rainfall in recent years.

Therefore, to minimize risks, businesses need to perform regular maintenance and renovate deteriorated components. In particular, industrial metal roof leak prevention is not just a temporary solution but also a necessary investment for the long-term stability of the facility.

3. Signs indicating when factory roof leak repairs are needed during the rainy season

Many factories ignore minor early signs and only act when prolonged rains reveal widespread leakage requiring urgent industrial metal roof leak prevention.

- The metal roof shows yellow stains, peeling paint, or water rust in certain areas.

- Roof screws are loose, bent, or missing their rubber protective caps.

Image 3. Signs indicating the need for factory renovation

- Walls near the ceiling show small cracks or unusual mold stains.

- The interior space has a strong musty odor after rain.

- Rainwater accumulates for a long time around the factory area, causing flooding if the drainage system is not renovated promptly.

- The electrical and lighting system flickers or loses power after rain.

- Weld joints and steel column bases show widespread rust.

4. Comprehensive solutions for metal roofs, drainage systems, and steel framework

Waterproofing metal roofs: Replace severely rusted sheets, seal joints and screws with silicone adhesive, then apply waterproof coating to complete roof leak repairs.

Solution 1: Upgrade the drainage system to prevent factory flooding

- Clear all drainage pipes and check the roof’s slope.

- Replace gutters with new galvanized steel or stainless steel ones, featuring anti-rust coating.

- Add additional water inlets and drainage outlets at water accumulation points.

- Strengthening the factory floor is a common task in renovation projects to reduce factory flooding during the rainy season.

Image 4. Skilled engineers & workers repairing leaky roofs

Solution 2: Anti-rust coating for steel framework

- Clean the steel structure surface using sandblasting or mechanical grinding methods.

- Apply two layers of anti-rust paint followed by a protective topcoat for color preservation.

- Use high-quality epoxy or polyurethane paint.

Solution 3: Upgrade the electrical system for rainy season safety

- Inspect and replace damaged or exposed electrical wiring.

- Install a leakage protection system (circuit breakers with ground fault protection).

- Enhance insulation coverings and raise electrical outlets above ground level.

- Relocate electrical equipment away from flood-prone areas.

These solutions ensure more reliable operations throughout the rainy season. Among them, industrial metal roof leak prevention remains a crucial factor in minimizing disruption and avoiding unnecessary damage.

5. US Buildings – Fast factory maintenance solutions for your business

Early inspections help reduce rust, flooding, and improve industrial metal roof leak prevention efficiency. Factories should schedule regular renovations every 6–12 months, especially before the rainy season.

US Buildings is one of the most experienced service providers in maintenance, renovation, and especially industrial metal roof leak prevention for factories in Southern Vietnam. We have successfully completed numerous projects for medium and large-sized enterprises.

- Free inspection and transparent, detailed quotations provided.

- A skilled team of engineers and workers delivering fast, precise, and professional service.

- Genuine materials ensuring high durability and suitability for the local climate.

- Clear warranty policies with ongoing support for regular maintenance.

Hundreds of businesses in Ho Chi Minh City, Binh Duong, Long An, and the Mekong Delta have trusted US Buildings for industrial metal roof leak prevention during the rainy season.

The rainy season in the Southern region always poses significant risks to factory systems if not regularly and properly inspected. Investing in comprehensive factory leak prevention solutions not only helps businesses maintain stable production but also saves substantial costs compared to repairs after severe damage occurs.

Image 5. Rapid response team for metal roof leak prevention in factories

If you’re looking for a reliable, fast, and efficient partner this rainy season, don’t hesitate to contact US Buildings Vietnam for a free consultation and tailored solutions to repair leaking roofs or optimize factory renovation for the rainy season.

Contact us now at 0976 795 951 or leave your information here to receive a completely FREE technical consultation and schedule a survey with our expert team!